Dansk AM Hub udvider med nyt teknologilaboratorium i Frederikssund

Dansk AM Hub udvider med nyt teknologilaboratorium i Frederikssund

Danmark har fået en ny platform for fremtidens produktion. Dansk AM Hub, der arbejder for at gøre Danmark førende i brugen af ny produktionsteknologi og 3D-print, udvider nu sin fysiske tilstedeværelse og etablerer AM-Lab Øst i Frederikssund – en pendant til det veletablerede AM-Lab Vest i Herning.

Det nye AM-Lab Øst skal styrke innovation og bæredygtighed i produktionsvirksomheder på Sjælland og bliver et samlingspunkt for virksomheder, uddannelsesinstitutioner og offentlige aktører med interesse for avanceret produktion og metal-3D-print. I den forbindelse søger Dansk AM Hub en ny innovationsrådgiver, der skal være med til at føre visionerne ud i livet.

”Vi oplever stor interesse for ny produktionsteknologi i hele landet, men også en mangel på viden – og konkrete tilgange til – hvordan en producent kommer i gang, for sorteret i de mange muligheder og får lavet en konkret strategi så de får rykket produktionen i en mere konkurrencedygtig og bæredygtig retning. I Herning har vi skabt stærke resultater i samarbejde med Herningsholm Erhvervsskole og Herning Kommune. Nu er tiden kommet til at udvide indsatsen på Sjælland – og her er Frederikssund det helt rette sted,” siger Frank Rosengreen Lorenzen, direktør i Dansk AM Hub.

Et stærkt lokalt samarbejde i Frederikssund

AM-Lab Øst placeres centralt på Campus Frederikssund og etableres i et tæt samarbejde med bl.a. Frederikssund Kommune, Frederikssund Erhverv, Campus Frederikssund, Dansk Industri og DTU. Med avanceret metal-3D-print, udviklet af DTU, vil laboratoriet være med til at gøre ny teknologi mere tilgængelig for små og mellemstore virksomheder i regionen.

”Der er et stærkt lokalt engagement i Frederikssund. Med kommune, erhvervsliv og uddannelsesinstitutioner ombord er der gode muligheder for at skabe konkret værdi for både virksomheder og unge i området,” udtaler Frank Rosengreen Lorenzen.

Borgmester i Frederikssund Kommune, Tina Tving Stauning, glæder sig over etableringen:

”I Frederikssund har vi et stærkt erhvervsliv og et unikt samarbejde på tværs af kommune, virksomheder, uddannelsesinstitutioner og arbejdsmarkedets parter og endda med vores lokale medlemmer af Folketinget. Vi er stolte af at kunne tiltrække et nationalt projekt som AM-Lab Øst til Campus Frederikssund. Det viser, at vi lykkes med vores visioner. Byrådet har desuden prioriteret at medfinansiere initiativet sammen med Industriens Fond – og det er en investering i fremtiden,” siger Tina Tving Stauning.

Succesen i Herning viser vejen

AM-Lab Vest åbnede i Herning i 2022 og har siden hjulpet adskillige produktionsvirksomheder med at komme i gang med additive teknologier. Her har Dansk AM Hub samarbejdet med Herning Kommune, DAMRC, AU Herning og Herningsholm Erhvervsskole om at gøre 3D-print i metal til en styrkeposition i Midt- og Vestjylland.

“Vi har vist i Herning, at når offentlige og private aktører løfter i flok, kan vi rykke på både konkurrenceevne og bæredygtighed i industrien. Det vil vi nu gentage i Østdanmark,” siger Steffen Schmidt, CTO i Dansk AM Hub, som til hverdag har base på AM-Lab Vest i Herning.

Med åbningen af AM-Lab Øst skal Dansk AM Hub ansætte en innovationsrådgiver med erfaring inden for avanceret produktion, automatisering eller værdikædeoptimering. Stillingen indebærer tæt samarbejde med virksomheder, rådgivning om teknologi og udvikling af konkrete business cases og CO₂-beregninger.

Print og byg: Kan 3D-print i stor skala blive et nyt værktøj for byggebranchen?

Print og byg: Kan 3D-print i stor skala blive et nyt værktøj for byggebranchen?

Mindre materialeforbrug, lavere CO2 udledninger, nye og mere biobaserede materialer og større designfrihed. En ny rapport fra Dansk AM Hub viser, hvorfor 3D-print kan være et redskab, der giver byggeriet helt nye og mere bæredygtige muligheder.

Byggeriet spiller en afgørende rolle i samfundet og skaber rammerne for vores hverdag. Samtidig er det en sektor med et stort ressourceforbrug og en væsentlig klima- og miljøpåvirkning. Derfor bliver det stadig vigtigere at undersøge nye veje og teknologier, der kan gøre byggeriet mere bæredygtigt – fx ved at tage helt nye redskaber i brug.

En ny rapport fra Dansk AM Hub støttet af den filantropiske forening Realdania undersøger 3D-prints potentiale i byggeriet. Og der er meget at komme efter.

”3D-print har store fordele i forhold til konventionelt byggeri og vores rapport viser en stor samling af de mange fantastiske projekter, der er overalt i verden, hvor der eksperimenteres med nye materialer, design og 3D-print. Da bygningen eller bygningsdelene bliver printet lag for lag, kan du tilpasse mængden af materialer til det enkelte byggeri ude på byggepladsen. Du kan også specialdesigne konstruktioner, der optager kræfterne helt præcist, så du undgår overdimensionering. I begge tilfælde undgår du overforbrug af materialer,” siger innovationschef i Dansk AM Hub Birgitte Arendsdorf Olsen.

Print med biobaserede byggematerialer

Et lavere materialeforbrug giver markant mindre affald og et reduceret CO2 forbrug. Samtidig er 3D-print en genvej til flere nye og eksperimenterende materialer. Printeren kan fx fodres med genbrugsplast eller biobaserede materialer som hamp, ålegræs og ler. Ligesom, at der kan skabes fx paneler hvor skallen er printet af genbrugsplast og fyldet er lavet af biogent materiale som mycelium.

”I Barcelona har de printet et hus med lokal jord gravet på stedet. Jeg kan sagtens se for mig, at man høster materialerne til bygningen direkte på byggepladsen i fremtiden. Prøv at tænke hvor meget transport vi kunne spare, hvis bare 10% af materialerne på grunden kunne bruges direkte i bygningen, siger Birgitte Arendsdorf Olsen.

Manglende viden om 3D-print

3D-print kan også kræve færre mandetimer end traditionelt byggeri, giver større designfrihed og mulighed for at bygge bygninger, som let kan skilles ad. Trods de mange fordele ved teknologien er der dog stadig langt mellem de 3D-printede bygninger i Danmark. Det skyldes, at der er mange fordomme om æstetikken, der mangler viden om teknologien, og så spænder den nuværende lovgivning ben for mere eksperimenterende materialer.

Derfor er der brug for mere partnerskab på tværs af byggeriets værdikæde for at få gevinsterne i spil, mener Birgitte Arendsdorf Olsen:

”Vi har brug for flere partnerskaber mellem producenter af biobaserede byggematerialer, producenter indenfor 3D-print og vidensinstitutioner, hvis vi skal løfte teknologien til næste niveau. Vi skal også have flere pilotprojekter på banen, så vi kan udbrede kendskabet til teknologien og nedbryde fordommene omkring 3D-print. Og ja, så har vi brug for et bygningsreglement, som er mindre konservativt overfor nye materialer. Der er nok at tage fat på. Men hvis vi knækker koden, kan vi skabe et helt nyt og meget mere cirkulært byggeri,” slutter Birgitte Arendsdorf Olsen.

Rapporten AM in Construction

Rapporten AM in Construction er forfattet af Dansk AM Hub med bidrag fra Molio, Contec Lab og HD Lab.

Rapporten er støttet af Realdania og Industriens Fond.

AM Summit vender tilbage i 2025 i nyt format med fokus på små og mellemstore virksomheder

PRESSEMEDDELELSE

København, 17. juni 2025

AM Summit vender tilbage i 2025 i nyt format med fokus på små og mellemstore virksomheder

Efter et succesfuldt AM Summit 2024 præsenterer Dansk AM Hub nu næste kapitel: AM Summit 2025: SME Edition. Den nye udgave bliver et mere fokuseret arrangement målrettet små og mellemstore produktionsvirksomheder, og finder sted den 1. oktober som en del af HI Tech & Industry Scandinavia i MCH Messecenter Herning.

Et skarpt fokus på SMV’er – midt i industrien

Hvor AM Summit 2024 samlede over 1.000 deltagere, 49 talere og 67 udstillere til en stor konference i København, tager AM Summit 2025 form som et mere målrettet arrangement midt i industrien – på og sammen med Danmarks største industrimesse, HI-messen, der afholdes 30. september til 2. oktober.

– Vi oplever en stigende interesse blandt danske produktions-SMV’er for at forstå og udnytte potentialet i 3D-print og Additive Manufacturing. Derfor vælger vi i år at bringe AM Summit helt tæt på industrien og den daglige virkelighed – og gør det midt i det pulserende industrimiljø på HI-messen, siger Frank Rosengreen Lorenzen, direktør i Dansk AM Hub, og fortsætter:

– Med AM Summit 2025: SME Edition giver vi målgruppen en koncentreret og praksisnær oplevelse med ny viden, konkrete cases og netværk. Vi ser store synergier i at kombinere konferencen med HI-messen, og vi tror på, at dette format vil ramme plet for de virksomheder, vi ønsker at inspirere og hjælpe videre i deres AM-rejse.

Koncentreret program med stor værdi

Dagen byder på et inspirerende program med fem keynote-oplæg fra både danske og internationale virksomheder samt seks udvalgte Tech Talks med fokus på konkrete AM-anvendelser i industrien. Herefter sendes deltagerne ud på egen opdagelse i 3D Tech-området i Hal K, hvor Dansk AM Hub også har egen stand.

3D Tech-området samler en lang række udstillere inden for 3D-print og Additive Manufacturing og huser i år også det spændende DM i 3D-print for erhvervsskoler, som Dansk AM Hub er stolt samarbejdspartner på.

Gratis deltagelse – men begrænsede pladser

AM Summit 2025: SME Edition er gratis at deltage i og henvender sig særligt til SMV’er i den danske fremstillingsindustri – både virksomheder, der er nysgerrige på teknologien, og dem, der er klar til at tage næste skridt. Arrangementet er også en oplagt mulighed for at stifte bekendtskab med Dansk AM Hubs virksomhedsforløb AM Sustain, som hjælper produktionsvirksomheder med at komme godt i gang med 3D-print.

Der er et begrænset antal pladser, og tilmelding sker efter først-til-mølle-princippet. Der vil desuden være lodtrækning blandt de første 100 tilmeldinger om 5 gratis overnatninger i forbindelse med AM Summit og HI-messen. Overnatningerne er sponsoreret af Industriens Fond.

AM Summit 2025: SME Edition

- Dato: 1. oktober 2025

- Sted: HI Tech & Industry Scandinavia, MCH Messecenter Herning

- Fokus: Additive Manufacturing for små og mellemstore produktionsvirksomheder

- Program: keynotes, Tech Talks, paneldebatter, netværk, guidet messebesøg og fuld forplejning

- Deltagelse er gratis, men der er et no-show gebyr på 799 kr.

- Begrænset antal pladser og maks. 2 deltagere pr. virksomhed

- Læs mere og tilmeld dig her.

For mere information, kontakt:

Rikke Uldall-Ekman

Communications & Event Manager hos Dansk AM Hub

+45 22 12 23 09

rue@am-hub.dk

ECOALF STORE

ECOALF STORE

Plastic Waste into Sustainable Design

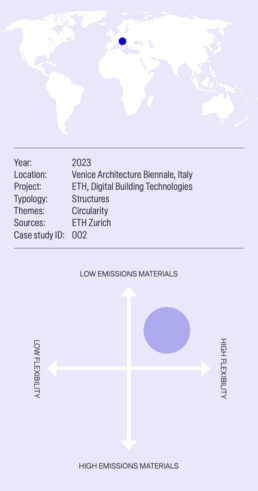

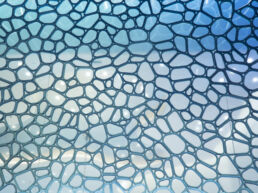

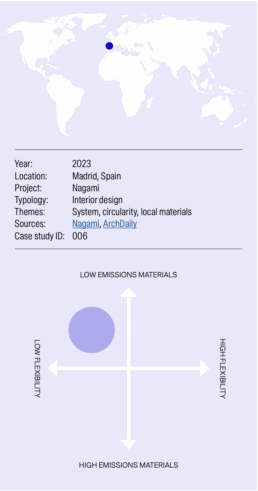

A net-zero, zero-waste boutique in Madrid is the result of a collaboration between Ecoalf and Nagami. The interior features walls, shelves and display tables entirely made from 3.3 tonnes of 100% recycled plastic. The components were 3D printed to resemble melting glaciers to raise awareness of climate change. The use of recycled plastic in the store’s construction not only diverts waste from landfill, but also showcases the potential of 3D printing technology in sustainable design. By sourcing materials locally in Spain and manufacturing components locally, the project minimises the carbon emissions associated with transportation and manufacturing. This approach provides a model for reducing the environmental impact of retail design, highlighting the feasibility of integrating recycled materials into commercial spaces.

RADICANT

RADICANT

Pioneering Sustainable Biopolymer Architecture

The project, developed by the Centre for Information Technology and Architecture (CITA) at the Royal Danish Academy, explores the use of biopolymer composites derived from agricultural waste streams to create a 3D printed wall paneling system. The composite material consists of bone glue, a by-product of the meat industry, combined with cellulose fibres from various waste streams. The mixture is robotically 3D printed into filigree leaflike patterns. Due to the thermoplastic properties of bone glue, the material can be reactivated and reshaped by localised heating, facilitating processes such as repair, refurbishment and recycling. Such adaptability supports the principles of circular design by allowing the material to be reused and reconfigured, thereby extending its life cycle and reducing waste. Radicant was part of the Living Prototypes exhibition at Aedes Architecture Forum in Berlin from 10.12.2022 – 25.01.2023.

3D PRINTED FILM STUDIO

3D PRINTED FILM STUDIO

3D printing and lighting fusion

In 2023, designer Philipp Aduatz, in collaboration with set designer Dominik Freynschlag and 3D concrete printing manufacturer incremental3d, developed the world’s first 3D printed film studio for the Casinos Austria and Austrian Lotteries Group. The studio features a concrete wall constructed from 60 individual segments, each produced using a special white cement-based mortar. These segments are assembled into a structure measuring 630 cm in width, 330 cm in depth, and 230 cm in height, with a total weight of 3,500 kg. The wall incorporates 14 horizontally inserted LED strips, each matching the thickness of the 3D printed layers. All LED elements are integrated into the studio’s lighting system via computer-aided control, enabling an almost unlimited number of color combinations. By combining 3D printing with smart LED technology, the project demonstrates a novel approach to studio design, offering new possibilities for creating unique atmospheres and enhancing the versatility of film production environments.

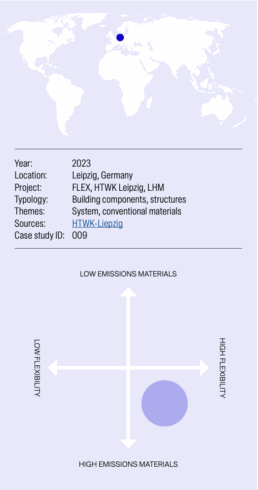

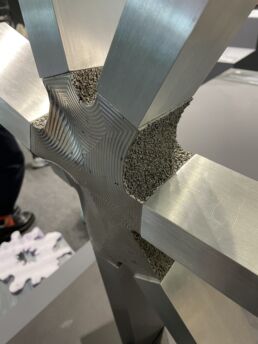

InNoFa-DEMONSTRATOR

InNoFa-DEMONSTRATOR

Individual node facades

The FLEX research group at the University of Applied Sciences Leipzig (HTWK) and the Laserinstitut Hochschule Mittweida (LHM) have developed the InNoFa2.0. The single-node façade component is manufactured using a new large-volume powder bed-based 3D printing technology that combines technologies from different additive manufacturing processes. These features greatly increase the material turnover during the process, reduce the printing time and lower the material costs. This technique holds great potential for larger components. The InNoFa2.0 demonstrator is based on the ParaKnot3D concept, a hybrid construction that combines straight rods and individual knot elements to create optimised free-form structures.

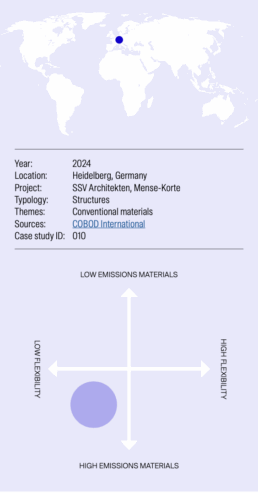

THE WAVE HOUSE

THE WAVE HOUSE

Europe’s largest 3D printed building

Europe’s largest 3D printed building, the Wave House Data Centre, was inaugurated in Heidelberg, Germany, marking a major milestone in innovative construction. The project, developed by PERI 3D Construction and HeidelbergCement, used COBOD’s BOD2 3D construction printer to build the structure. A key design challenge was overcome by architects SSV and Mense Korte, who incorporated a unique wave design into the walls. Such intricate wave-shaped walls would not have been possible using conventional construction methods, so 3D printing was chosen for its design flexibility. The building demonstrates the potential of 3D printing to create complex, energy-efficient structures and provides a scalable solution for future data centre developments.

STRESS-BASED DESIGN

STRESS-BASED DESIGN

For 3D concrete printed horizontal structures

DLightBeam+ is the second iteration of the 3DLightBeam research project, which aims at combining computational design with the freedom of shape provided by the 3D Concrete Printing (3DCP) technology to challenge conventional reinforced concrete structures by exploring new design solutions for carbon-efficient concrete beams. 3DLightBeam+ enables structurally reliable load-bearing printed beams with carbon reduction through multi-hierarchical stress-based design optimization. 3DLightBeam+ is shape-optimised to maximise bending capacity while reducing weight. Its internal infill design is inspired by the layout of the structure of bones, to work in pure compression and tension. A high-resolution material deposition is achieved by data-driven robot control, allowing us to deploy concrete and steel reinforcements only where needed, avoiding material inefficiencies. The structure can be applied in existing construction sites and, at this stage, reduce concrete CO2 emissions by 19.3 %.

TIFFANY FAÇADE

TIFFANY FAÇADE

Coral-inspired 3D-printed façade

The Tiffany & Co. store façade designed by MVRDV features a coral-inspired screen, 3D printed using recycled plastic thanks to the assistance of Amsterdam-based company Aectual and Milan-based engineers BUROMILAN. Using the patterns seen in Singapore’s coral reefs as a guide, the team designed a screen to cover the store’s façade with an organic, cell-like pattern. 3D printing experts developed a process to produce the 50 millimetre thick screen using recycled plastic, including reclaimed and recycled fishing nets. By making use of this unusual source of recycled plastic, the design not only draws inspiration from the oceans, but also plays a part in protecting them. A particularly challenging task was to meet the stringent regulations for fire safety required in an airport, solved by adding a chemical to the mixture that is also manufactured using seawater.