CERAMIC HOUSE

CERAMIC HOUSE

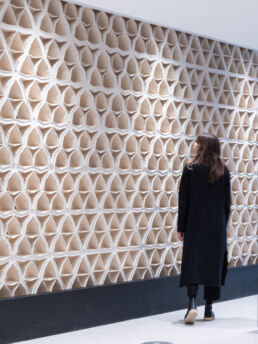

A facade inspired by knitwear

Through a creative interplay of 3D printed ceramic tiles and imaginative design, Studio RAP fused tradition and modernity, drawing inspiration from knitwear and the city’s rich ceramic heritage. The building’s facade is made up of 225 unique tiles – 3D printed ceramic tiles that mimic the appearance of rippling textiles. Fired at high temperatures to ensure durability and weather resistance, the tiles were produced using a clay 3D printing process, with each tile taking approximately two hours to print. The wavy, textile-like texture of the tiles was achieved by precisely controlling the layering during the printing process, creating a three-dimensional effect that enhances the visual depth of the façade and integrates seamlessly with traditional construction methods.

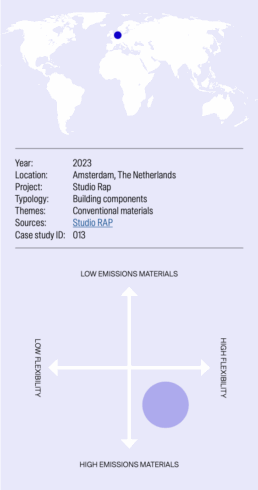

WOHN HOMES

WOHN HOMES

Redefining sustainable housing in 3D printing

WOHN A/S pioneers sustainable housing through advanced 3D printing, repurposing waste wood, glassfiber, and plastic for affordable, sustainable homes. Each 20m² home reuses 3 tons of waste, reducing CO2 emissions by 90% compared to traditional construction methods. The technology ensures high-quality, customizable designs without added costs, empowering homeowners to personalize spaces sustainably. These homes last over 60 years, designed for efficient recycling at their lifecycle’s end, reflecting WOHN’s commitment to sustainability.

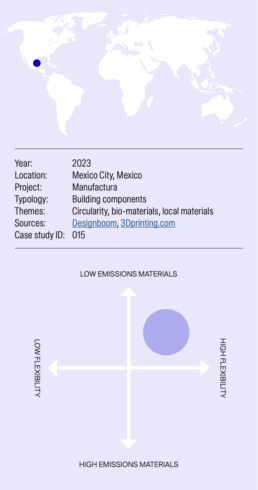

THE EGGSHELL PROJECT

THE EGGSHELL PROJECT

Giving new life to biowaste

MANUFACTURA, a Mexican design studio, has launched ‘The Eggshell Project’ with the aim of transforming organic waste into sustainable building materials. With food waste accounting for a third of global production, this project seeks to address both environmental and socio-economic issues by reusing discarded eggshells. The project focuses on using these eggshells in combination with bio-binders to create bioceramic bricks, eliminating the need for traditional firing processes. The mixture is 3D printed into various geometric shapes, resulting in building components suitable for a variety of architectural applications. The research led to the development of two primary structures: the Eggshell Wall, made up of 105 unique blocks that are assembled based on their geometry, and the Eggshell Column, made up of 26 interlocking pieces that provide stability through their shape. The eggshells used were collected over two months from various restaurants in Mexico City, ensuring a 100% sustainable and circular process. By integrating computer-aided design with digital manufacturing, the project demonstrates the potential to transform organic waste into valuable building materials.

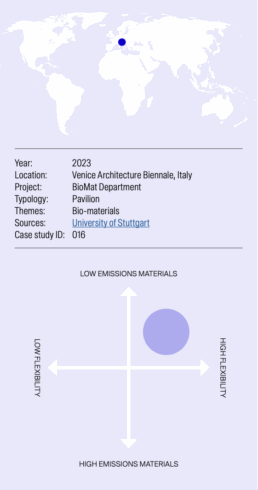

3DNATURDRUCK

3DNATURDRUCK

Biocomposite Reciprocal Canopy

The project explores 3D printing in combination with annually renewable natural fibres, focusing on material development, structural analysis, fabrication methods and the application of this material-based technique to architectural design. Specifically, the study investigates the use of 3D printed natural fibre reinforced filaments in different architectural contexts, tested through a series of demonstrators addressing different design challenges. The structure was fabricated using a lightweight short fibre filament composed of wood fibres and bio-based PLA. As the material was developed specifically for this project, extensive testing was carried out to inform the digital simulations and to ensure the integrity of the structure. These tests have been instrumental in refining the printing process and validating the performance of the material for architectural applications. The project lays the groundwork for the integration of natural fibre-based 3D printing in construction.

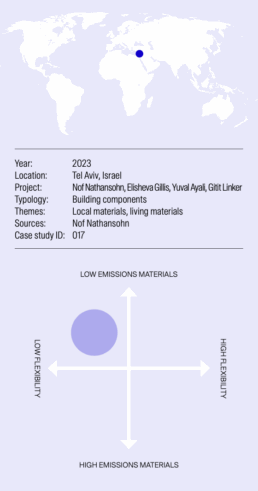

TO GROW A BUILDING

TO GROW A BUILDING

Totem

To Grow a Building is a research-driven project exploring sustainable architecture through the utilization of 3D-printed structures crafted from locally sourced soil and plant seeds, allowing the seeds to germinate and grow after printing. The roots intertwine within the structure, providing natural reinforcement and strength, reducing the need for traditional building materials. The project aims to combine the precision of digital fabrication with the natural adaptability of plants, contributing to sustainability and the preservation of local plant species. This innovative method was tested by creating a totem-like structure with different geometries and seed types, which was placed in a garden setting where the plants grew, some even reaching harvestable heights.

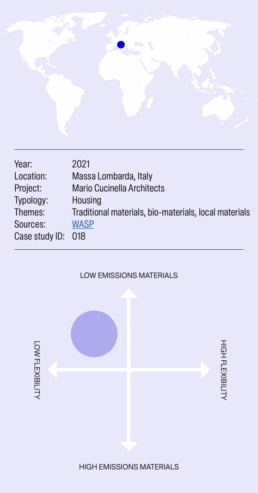

TECLA

TECLA

House 3D printed with local soil

TECLA is a fully 3D printed housing unit that integrates traditional building techniques with natural, locally sourced materials. Designed by Mario Cucinella Architects (MCA) and engineered by WASP, it uses recyclable materials from the local soil, making it carbon neutral and adaptable to different climates. The double-dome design combines structure, roof and cladding to ensure efficiency. It was built using two synchronised 3D printers, using automation protocols to optimise movement and efficiency. The soil mix was tailored to local climatic conditions, with solar analysis and computational tools guiding the design to improve thermal performance and energy efficiency. (Chadha, et al., 2024

REEFCIRCULAR

REEFCIRCULAR

Turning shell waste into sea life

ReefCircular is dedicated to restoring marine ecosystems transforming shell waste into 3D printed artificial reef structures designed to mimic natural habitats. The ReefKasse system, a modular artificial reef tile, can be easily installed on harbour walls and underwater structures, providing an ideal surface for marine organisms to attach and grow, helping to counteract habitat loss in urban coastal areas. In Hundested, Denmark, 24 artificial reef tiles have been installed to create complex habitats for small fish, seaweed and invertebrates on seawalls and seafloor. The installation process is efficient, taking as little as 30 minutes and requiring no dive teams, making it an accessible solution for biodiversity restoration. The system is currently being tested in clay, which has lower CO2 emissions than concrete, and will be available in shell-based bioconcrete from 2026.

AIRLEMENTS

AIRLEMENTS

Insulated Walls with Sustainable Mineral Foam

Airlements project, developed by researchers at ETH Zürich in partnership with FenX AG, employs large-scale robotic 3D printing to create monolithic, lightweight, and insulated wall systems using cement-free mineral foam crafted from recycled waste. This innovative material, with varying densities, optimizes thermal performance and energy efficiency, reducing operational energy needs for heating. The Airlements prototype showcases rapid, low-energy 3D printing, each 25 kg hollow segment hardening over a week without energyintensive processes. The technology’s versatility allows for non-structural exterior walls and seamless integration of reinforcements.

TOVA

TOVA

3d-printed Earth Architecture

The Institute for Advanced Architecture of Catalonia (IAAC) has developed

TOVA, Spain’s first 3D printed earth building, located at the IAAC’s Valldaura

Labs near Barcelona. Built in seven weeks using the Crane WASP 3D printer,

TOVA uses 100% local materials sourced within a 50-metre radius, resulting

in zero waste and minimal carbon emissions.

The walls of the structure are made of local soil mixed with additives and

enzymes to improve structural integrity and elasticity for optimised 3D print-

ing. The foundation is made of geopolymer and the roof is made of wood.

TOVA serves as a prototype bridging traditional earthen architecture and

modern 3D printing technology, offering a potential solution to current

climate and housing challenges.

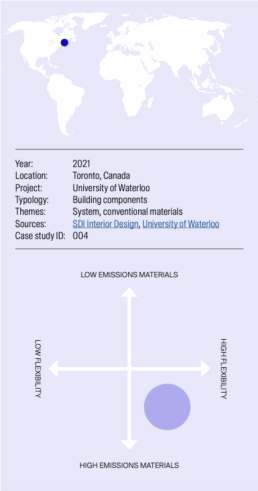

HIVE Project

HIVE PROJECT

Traditional Craftsmanship and Digital Innovation

The HIVE project is a 3D printed masonry wall built by a team from the University of Waterloo in Toronto, Canada. Designed by SDI Interior Design for Investment Management Corporation of Ontario, the wall is made of 175 unique 3D printed clay bricks, each designed with different openings to balance privacy and light transmission. The hexagonal aggregation of these units creates a structurally efficient form reminiscent of a honeycomb. The development process involved extensive testing of materials, designs and manufacturing techniques. The team combined traditional ceramic materials with advanced geometric design and robotic precision to achieve the final structure. This approach blends the principles of traditional ceramic craftsmanship with modern technology, allowing for new forms of material expression and geometric complexity in masonry construction.