InNoFa-DEMONSTRATOR

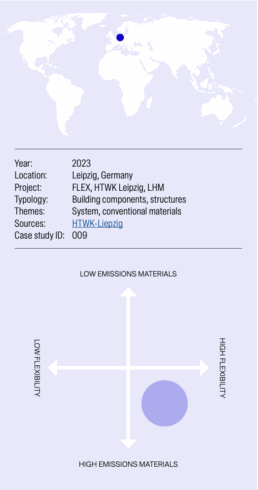

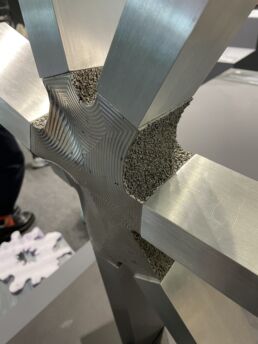

Individual node facades

The FLEX research group at the University of Applied Sciences Leipzig (HTWK) and the Laserinstitut Hochschule Mittweida (LHM) have developed the InNoFa2.0. The single-node façade component is manufactured using a new large-volume powder bed-based 3D printing technology that combines technologies from different additive manufacturing processes. These features greatly increase the material turnover during the process, reduce the printing time and lower the material costs. This technique holds great potential for larger components. The InNoFa2.0 demonstrator is based on the ParaKnot3D concept, a hybrid construction that combines straight rods and individual knot elements to create optimised free-form structures.

Related Posts

16/06/2025

ECOALF STORE

16/06/2025

RADICANT

16/06/2025

3D PRINTED FILM STUDIO

16/06/2025

THE WAVE HOUSE

16/06/2025

STRESS-BASED DESIGN

16/06/2025

TIFFANY FAÇADE

16/06/2025

CERAMIC HOUSE

16/06/2025

WOHN HOMES

16/06/2025

THE EGGSHELL PROJECT

16/06/2025

3DNATURDRUCK

16/06/2025

TO GROW A BUILDING

16/06/2025

TECLA

16/06/2025

REEFCIRCULAR

16/06/2025

AIRLEMENTS

16/06/2025

TOVA

16/06/2025

HIVE Project

16/06/2025

HEXASTONE

11/06/2025