3D-print åbner dørene for nye kundedialoger og mere effektiv produktion for KC Denmark

KC Denmark

Produkt:

Antal medarbejdere:

Produktion:

Prøvetagningsudstyr til forskning

18

Silkeborg

Fordele ved 3D-print i forhold til den nuværende løsning

90%

lavere lead time

25%

besparelse på enkelte komponenter

3D-print åbner dørene for nye kundedialoger og mere effektiv produktion

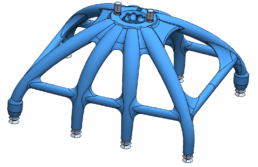

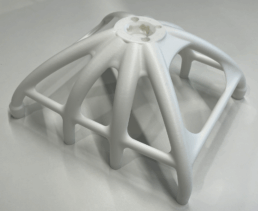

KC Denmark, som fremstiller specialiseret prøvetagningsudstyr til bl.a. havbundsprøver, har over de sidste to år investeret i både udstyr og kompetencer til at fremstille færdige komponenter til deres produkter gennem 3D-print.

De har allerede opnået større besparelser på at printe komponenter, som er dyre at fremstille med traditionel bearbejdning, og som har kunne nedbringe lagerbeholdningen til det højst nødvendige.

Forløbet med Dansk AM Hub

Med AM Sustain-forløbet gik KC Denmark ind for at arbejde med spørgsmålet; hvad er de næste forretningsmuligheder, hvis vi investerer endnu mere i 3D-print? Dansk AM Hub og KC Denmark evaluerede produktporteføljen og fandt to centrale muligheder:

- Simplicitet i produkter og lavere samleomkostninger

- Hurtigere at kunne tilbyde specialiserede produkter til nye kunder

På baggrund af træning og sparring omkring specifikt produktdesign står kernegruppen i KC Denmark nu med en mulighed for at konsolidere antallet af enkeltdele i et af deres nøgleprodukter og dermed spare samletid. Samtidigt kan de kritisk evaluere, hvordan de forskellige 3D-printteknologier giver dem muligheder, og vurdere en differentieret produktionsstrategi; inhouse fremstilling eller inhouse design og fremstilling hos leverandør.

Resultater og potentiale

Resultatet viser potentialet klart:

- Muligheder for hurtigere at udvikle og teste nye, specialiserede produkter med nye kundesegmenter

- Mindre afhængighed af eksterne leverandører og dermed højere agilitet i produktionen

- Omkostningsbesparelser på produkter hvor kompleksiteten eller serie-størrelsen gør det dyrt at fremstille med traditionelle værktøjer

Nysgerrig efter at vide mere?

Dansk AM Hub lancerer nationalt netværk for metal 3D-print: Skal modne teknologien i dansk industri

Dansk AM Hub lancerer nationalt netværk for metal 3D-print: Skal modne teknologien i dansk industri

Metal 3D-print er allerede i fuld drift i globale industrisektorer som luftfart, bilindustrien og energi, hvor teknologien ændrer måden komponenter designes, produceres og vedligeholdes. I Danmark er potentialet stort, men adoptionen går langsommere. Derfor lancerer Dansk AM Hub nu et nyt landsdækkende netværk for metal additive manufacturing (AM), som skal hjælpe danske produktionsvirksomheder med at modne teknologien og omsætte den til reel værdi i forretningen.

”Vi oplever, at mange danske virksomheder ser potentialet i metal 3D-print, men det tager ikke fart i den skala, vi ved teknologien kan,” siger Frank Rosengreen Lorenzen, direktør hos Dansk AM Hub. ”De står med de samme spørgsmål: Hvor er de værdifulde use cases? Hvordan bygges kompetencer og partnerskaber? Og hvordan integrerer man teknologien i en eksisterende produktion?”

Dansk industri mangler det naturlige aftræk

I lande som Tyskland, USA og Frankrig har især fly-, bil- og forsvarsindustrien trukket udviklingen af metal AM fremad. Det afsæt har Danmark ikke. Samtidig arbejder mange danske producenter i lavere volumener, hvor investeringer i nye processer kræver større sikkerhed, modenhed og sparring i værdikæden.

Det betyder, at teknologien – på trods af et stort potentiale – endnu ikke er skaleret bredt i Danmark. Det nye netværk skal adressere præcis det hul.

Stort potentiale for danske styrkepositioner

Kombinationen af metal og additiv fremstilling giver nye muligheder inden for blandt andet:

- Optimerede komponenter til maskiner og robotter, hvor vægtreduktion og designoptimering giver lavere energiforbrug og bedre performance

- On-demand reservedele til f.eks. energi- og offshore-industrien, hvor udgåede eller nedslidte komponenter kan vedligeholdes eller produceres hurtigere og uden dyre værktøjer

- Integrerede funktioner i værktøjer, som kølekanaler i støbeforme eller komplekse varmevekslere, der reducerer samlinger og fejlmuligheder

Teknologien er særligt relevant for Danmarks styrkepositioner inden for energi, offshore og avancerede industrikomponenter.

Efterspurgt af industrien

Netværket etableres på opfordring fra flere danske produktionsvirksomheder, der efterlyser et forum til at dele praktiske erfaringer, få adgang til eksperter og udvikle en fælles forståelse af både teknologiens muligheder og dens forretningsmæssige implikationer.

”Det, industrien efterspørger, er ikke kun teknisk viden, men et trygt rum for at diskutere strategi, forretning og implementering. Ingen skal stå alene med en ny teknologi, hvor usikkerhed stadig er en barriere,” siger Frank Rosengreen Lorenzen.

Netværket starter i 2026

Netværket henvender sig til danske producenter – eller internationale producenter med dansk tilstedeværelse – der enten har investeret i eller har ambitioner om at tage metal AM i brug.

Deltagerne får adgang til cases, facilitetsbesøg, ekspertoplæg og et fællesskab af virksomheder, der arbejder med de samme udfordringer.

Ansøgningsfristen er 20. januar 2026.

Julehilsen 2025

Julehilsen 2025

Hvad kan dansk industri lære af Hansi, Günther og Fritz?

Kære ven

Du er en af de knap 1.000 udviklere, producenter, innovatører, produktudviklere, ejerledere og samarbejdspartnere, som modtager vores nyhedsbrev. Du har sandsynligvis været en del af vores aktiviteter, rådgivning eller events – og denne hilsen er først og fremmest for at sige tak for samarbejdet og for at ønske dig og dine en rigtig glædelig jul.

Måske sidder du – ligesom jeg – og ser julekalender med ungerne. Jeg er heldig, for de er efterhånden så store, at vi kan se The Julekalender. Julekalenderen over dem alle. Et dansk klenodie, der nok har fået sin status, fordi den rammer noget dybt i folkesjælen.

De tre nisser, Fritz, Hansi og Günther, styrter ned på en jysk kartoffelmark i jagten på nøglen til spilledåsen, der holder deres chef, Gammel Nok, i live. Missionen er klar: Find nøglen til livet – ellers går det galt.

Den mission kan jeg godt genkende.

I snart en halv menneskealder har jeg arbejdet med det, der holder dansk industri i live: innovation. Evnen til at skabe og udvikle idéer og omsætte dem til virkelighed. Skabe noget nyt. Levere mere. Gøre en reel forskel.

På trods af de mørke udsigter vi tit bliver præsenteret for i Draghi-rapporter mv., vil jeg vove den påstand, at vi i Danmark er verdensmestre i netop den disciplin. Det forklarer også, hvorfor vi har tusindvis af små- og mellemstore producenter der slår kineserne hver dag, og nogle af verdens fremmeste producenter som Grundfos, Danfoss, Lego, Novo osv. Vi har ikke Tysklands størrelse, Norges olie eller Sveriges jernmalm. Men vi har noget, som er mindst lige så værdifuldt:

Det åbne, flade og tillidsfulde produktionsgulv.

Da jeg for 6 år siden sagde ja til jobbet som direktør i Dansk AM Hub, vidste jeg godt, at indsatsen næppe ville blive den største i Danmark. Men pga. kombinationen mellem det danske produktionsgulv og AM-teknologien var jeg helt overbevist om, at Dansk AM Hub kunne blive den bedste danske erhvervs- og innovationsindsats nogensinde. (Her ville Benny nok sige: “Bob Bob Bob” – men tro mig, jeg ser resultaterne).

For ja, Additive Manufacturing og 3D-print har en teknisk side, som skal mestres. Men endnu vigtigere er den idégenererende og skabende proces, som følger med. Printeren bliver broen mellem den digitale og den fysiske verden – og på det åbne produktionsgulv kan vi drøfte idéer, teste dem med det samme, lære hurtigt og komme videre.

Så vores tilgang har altid været klar: Styrk innovationsprocessen tidligt. Lav hurtige – men grundige – livscyklus- og business case-vurderinger upfront. For det er her, at op mod 80 % af både økonomi og klimaaftryk fastlåses. Kan vi blot rykke den proces i en lidt bedre retning, men gøre det for hele industrien – så kan vi på dansk jord skabe de mest effektive og grønne produkter i verden. Det er bår’ dæjlig, A Saaaw: Det er bår’ dæjlig!

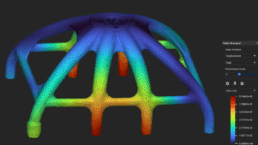

Med vores egenudviklede software kan vi nu gøre netop det. Lidt ligesom nisserne slår op i The Big Book, læner vi os op ad en unik kilde af data og viden – og hjælper virksomheder med at træffe bedre beslutninger tidligt i processen.

Vi er i dag den eneste erhvervs- og innovationsindsats, der kan vise i hvilke scenarier der skabes både forretningsmæssig, teknisk og bæredygtig effekt af vores arbejde med vores dygtige producenter.

Så nu slynger jeg lige en bemærkning ud i luften ik?: Det er da konkret. Det er da dét, Draghi taler om. Og jeg skal hilse at sige: Det virker.

Det har kun kunnet lade sig gøre, fordi vi har haft tid og ro til at udvikle tilgangen. Derfor skal der også lyde en stor tak til Industriens Fond, hvor vi næste år tager hul på vores tredje bevilling.

For den nye bevilling har gjort det muligt at integrere vores software og samle vores erfaringer fra mere end 400 rådgivningsforløb i én tilgang: AM SUSTAIN. Og jeg har ærligt talt aldrig set stærkere resultater end hos de over 30 små og mellemstore producenter, vi har hjulpet i år med denne tilgang.

Ingen nævnt, ingen glemt – men jeg vil gerne sige: Godt gået og tak for samarbejdet til jer alle.

Vi har også gennem året haft mulighed for at teste AM SUSTAIN i stor skala hos større producenter som fx FUJIFILM Biotechnologies og Alfa Laval – mange tak for samarbejdet til jer alle. For hvis vores tilgang ikke kan skabe værdi hos jer, er den heller ikke god nok til de travle SMV’er, vi arbejder med hver dag.

Jeg tror, at grunden til, at vores tilgang skaber så meget værdi, er dels den kompetence, vi nu har opbygget i Dansk AM Hub – hvor jeg har et fantastisk stærkt team, som arbejder lige så hårdt som Hansi – men mest af alt, at vi ikke kun som Günther snitter/3D-printer en propel til vores virksomheder. Nej vi stopper først, når vi har skabt en helt ny kompetence hos vores virksomheder, der så selv kan snitte fremtidens mest effektive produkter og løsninger.

Den kompetence er en innovationsmotor, der sikrer, at det er os i dansk industri, der finder de nye løsninger, og at vi ikke bliver overhalet af udlandets nåsåer.

Så lad os samarbejde, skabe og bygge noget sammen – for vi kan skabe fantastisk værdi ved at kombinere AM, AI, konkrete cases på fabriksgulvet og klare beregninger af potentiale, skalering og implementering. Det er nøglen til livet i dansk industris konkurrencekraft. Og det er det, Dansk AM Hub ånder og lever for.

Så jeg er både stolt og taknemmelig over at stå i spidsen for en indsats, der lærer, udfordrer sig selv, og leverer målbar værdi. En indsats, der arbejder med virksomhederne i stedet for at drukne dem i ansøgningsskemaer, timesedler og bøvl. (That’s a good vending)

For resultaterne taler for sig selv.

Jow, déeeeet…

Med de bedste julehilsner

Frank Rosengreen Lorenzen

Direktør, Dansk AM Hub

Er du endnu ikke skrevet op til vores nyhedsbrev?

Cirkularitet i Produktionshallen: Nyt projekt sætter fokus på levetidsforlængelse i industrien

Cirkularitet i Produktionshallen: Nyt projekt sætter fokus på levetidsforlængelse i industrien

Hvordan kan danske produktionsvirksomheder styrke både konkurrenceevne og bæredygtighed uden at udskifte hele produktionsudstyret?

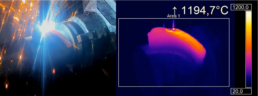

Det spørgsmål danner fundamentet for det nye initiativ Cirkularitet i Produktionshallen, der skal udvikle og demonstrere nye metoder til hybridfremstilling. Hybridfremstilling kombinerer subtraktive og additive processer, så slidte og fejlproducerede metalemner kan repareres og bringes tilbage i produktion. Samtidig undersøges mulighederne for at opgradere ældre CNC-maskiner og industrirobotter, så de får nyt liv frem for at blive skrottet.

Projektet gennemføres af DAMRC, Dansk AM Hub og Aarhus Universitet i samarbejde med Industriens Fond.

Ved hjælp af tests, demonstrationscases, events og hands-on viden skal projektet give især SMV’er i produktionsindustrien adgang til teknologier, der kan reducere materialespild, forlænge udstyrets levetid og skabe en styrket grøn profil – uden store investeringer i helt nye systemer.

Projektet løber til februar 2028, og de første aktiviteter er allerede sat i gang.

Vi glæder os til at dele erfaringer og resultater undervejs!

Velbesøgt Åbent Hus hos 3D Infill: Masser af nysgerrighed omkring 3D-print

Velbesøgt Åbent Hus hos 3D Infill: Masser af nysgerrighed omkring 3D-print

“Du betaler med din tid og dit engagement.”

Det var aftalen – og betale, dét gjorde deltagerne ved vores Åbent Hus hos 3D Infill i Slangerup tirsdag den 25. november. Ja, de lagde nærmest drikkepenge. For energien var høj, og nysgerrigheden endnu højere.

Deltagerne bestod af virksomheder, fagfolk og nysgerrige sjæle, der ønskede et tættere indblik i mulighederne med Additive Manufacturing (AM). Formålet med arrangementet var at give et ærligt og inspirerende indblik i 3D-printteknologi – hvad den kan, hvad den ikke kan, og hvordan danske virksomheder allerede anvender teknologien i praksis.

Der var masser af gode drøftelser og livlige samtaler om alt fra 3D-printede støbeforme til metalprint, design, cirkularitet og fremtidens kompetencer. Deltagerne kunne møde og tale med en række fagfolk og virksomheder, herunder Asgaard Metals, 3DPMolds, Carmo, Preject Studio, Industriens Uddannelser, Dansk Metal, Frederikssund Erhverv, 3D Infill og Dansk AM Hub. Standene og rundvisninger i 3D Infills produktionsfaciliteter gav konkrete eksempler på, hvordan AM allerede skaber værdi i industrien.

Dagen bød også på netværk, dialog og tid til at drøfte mulighederne for opkvalificering og videreuddannelse, så medarbejdere kan varetage AM-rollen i fremtidens produktion.

En særlig tak til dagens oplægsholdere og samarbejdspartnere for skarpe indsigter og konkrete eksempler på, hvordan 3D-print og AM skaber værdi i praksis

Se billeder fra dagen nedenfor.

Vi planlægger allerede flere Åbent Hus-arrangementer i 2026!

Skal vores næste arrangement afholdes hos din virksomhed? Eller har du ønsker til temaer eller input til indhold? Tag fat i Marianne Heidam, så kan vi sammen skabe rammerne for næste inspirerende dag.

Reduceret lead time og agilitet i produktionen med 3D-print

FUJIFILM Biotechnologies

Produkt:

Antal medarbejdere:

Produktion:

Gribearm

>2000

Hillerød

Fordele ved 3D-print i forhold til den nuværende løsning

1/6

af leveringstiden

1/8

CO2-udledning

Reduceret lead time og agilitet i produktionen med 3D-print

Fujifilm Biotechnologies er en international CDMO-aktør, hvor produktion i højt tempo og hyppige omstillinger er en naturlig del af forretningen. Med udvidelser af kapacitet og nye faciliteter er effektivitet og fleksible løsninger afgørende for at holde processerne skalerbare. Derfor er teknologier, der kan reducere flaskehalse og styrke robustheden i udstyret, særligt relevante for dem.

De kendte til 3D-print, men primært i små, ikke-kritiske prototype anvendelser, men søgte en måde at arbejde mere systematisk med additive løsninger der anvender allerede godkendte materialer. Ambitionen var at afprøve, om 3D-print kunne skabe agilitet i driften og reducere både tid, kompleksitet og lagerbinding.

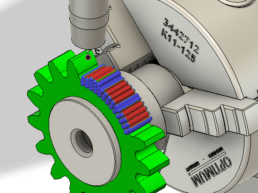

Forløbet med Dansk AM Hub

Igennem AM Sustain-forløbet omsatte vi i samarbejde med Teknologisk Institut en klassisk (fræset metal) vakuumgriber til en additivt optimeret løsning: markant lavere vægt, bedre vakuumfordeling og en design-konsolidering fra omkring 20 dele til én samlet komponent. Da komponenten skal operere i medicinal-produktion tog designet udgangspunkt i allerede godkendt materiale, og med øje for rengørings-venlighed og overflader der lever op til Fujifilms krav.

Udviklingsforløbet var bygget til hurtige iterationer og at kunne identificere det mest værdifulde sted at starte, så Fujifilm kunne få et pålideligt proof of concept uden at binde ekstra ressourcer eller tid.

Som led i forløbet blev kernemedarbejdere trænet, og kunne dermed omsætte de teknologiske muligheder, som metal- og (plast)pulver-teknologier, til at se et markant større potentiale end tidligere.

Resultater og potentiale

Resultatet viser potentialet klart: den 3D-printede griber kan leveres på en sjettedel af tiden, uden højere omkostninger og muliggør en betydelig reduktion i lagerbinding og flytransport. AM muliggør lokal produktion tæt på site, og man undgår flytransport når det haster – eller at have for mange dele produceret som ligger på lager. En øget digitalisering med print-optimerede emner giver mulighed for meget hurtigere ændringer og optimering af delkomponenter, som gør det realistisk at udvide andelen af 3D-printede emner uden tunge investeringer i interne design-kompetencer.

Det giver et springbræt til at skalere additive løsninger bredere i organisationen også på tværs af sites og landegrænser – fra hurtige interne emner til mere fleksibelt procesudstyr, efterhånden som kompetencer og praksis modnes.

Nysgerrig efter at vide mere?

Industriens Fond udpeger erfaren grøn strateg til bestyrelsen i Dansk AM Hub

Industriens Fond udpeger erfaren grøn strateg til bestyrelsen i Dansk AM Hub

Dansk AM Hub styrker bestyrelsen med udpegningen af Ingrid Reumert, Senior Vice President for Global Stakeholder Relations hos Ørsted.

Med over 20 års erfaring fra ledende poster i erhvervslivet er Ingrid Reumert en markant stemme i den danske og internationale debat om bæredygtighed, energi og grøn omstilling. Hun har bred erfaring inden for stakeholder relations, policy og regulatoriske forhold, geopolitik, ESG-strategi og energieffektivitet, og så har hun i sin karriere stået i spidsen for både forretningskritiske og samfundsmæssige agendaer.

Ud over sin rolle i Ørsted bidrager Ingrid aktivt som medlem af flere bestyrelser og advisory boards, herunder Copenhagen Business School Executive, WWF Verdensnaturfonden Presidium, Københavns Lufthavn, Tænketanken EUROPA og State of Green Denmark, samt er Adjungeret Professor hos CBS. Før Ørsted har Ingrid Reumert været ansat i Terma A/S, VELUX A/S samt i Europa-Parlamentet og på Christiansborg.

Bestyrelsesformand i Dansk AM Hub, Poul Skadhede, udtaler:

“Vi er meget glade for at kunne byde Ingrid velkommen i bestyrelsen. Hun kommer med en stærk kombination af strategisk ledelse, globalt udsyn og dyb indsigt i bæredygtighed. Hendes profil passer perfekt til Dansk AM Hubs ambition om at gøre Danmark førende inden for bæredygtig produktion, og jeg ser frem til at samarbejde med Ingrid om at bygge bro mellem teknologi, erhvervsliv og samfund.”

Ingrid Reumert siger om sin tiltrædelse:

“Dansk AM Hub spiller en vigtig rolle i at drive innovation og bæredygtighed i dansk produktion. Additive Manufacturing rummer et stort potentiale til at reducere spild, CO₂ og materialeforbrug og samtidig skabe nye forretningsmuligheder. Jeg ser frem til at bidrage til bestyrelsens arbejde og til at styrke samarbejdet med både erhvervslivet og andre aktører om at fremme en grønnere og mere konkurrencedygtig dansk produktion.”

Samtidig med udpegningen af Ingrid Reumert er Gitte Buk Larsen og Jacob Dirks trådt ud af bestyrelsen.

Den nye bestyrelse i Dansk AM Hub består således af:

- Poul Skadhede (formand), formand for Odense Maritime Technology

- Jacob Himmelstrup (næstformand), direktør, Regaco

- Tim Frank Andersen, Co-founder & Partner, Institute of AI

- Mads Kjøller Damkjær, Executive Director, CulturePulse, og Chair, Tomorrow Projects

- Ingrid Reumert, Senior Vice President, Ørsted

Job: Head of Digital

Head of Digital

Developing platform for informing sustainable product development decisions

Do you want to help strengthen the competitiveness and sustainability of Danish industry through new production technologies and Additive Manufacturing? Do you have experience in advanced manufacturing, product development, or building digital platforms – and the desire to create real change for the industry?

Then you may be the one to help us develop the tools we need to realize our mission as head of digital development, with a possibility for a co-founding role.

About us and the position

Danish AM Hub works to make Danish companies world leaders in the use of AM and new production technologies. We help them develop better products, processes, and business models with lower CO2 footprint, less waste, and greater resilience – for example through digital inventories, circular business models, and efficient design.

A key enabler in our future is to be able to support manufacturers with a few key tools to e.g. digitalize and simulate production processes, make sustainable product choices, and get the most from new manufacturing technologies.

Our first step is a proprietary CO2e calculator that helps companies realize the climate impact of their choices during product development and make sustainability-informed manufacturing decisions. We have developed a solid proof of concept together with leading actors in Danish industry, and we are ready to further develop and scale the calculator.

Your responsibilities

Your responsibility will be to drive the development and scaling of the tools the industry needs, initially the CO2e calculator. Together, we will establish and pursue the most promising scenarios for developing the platform. We see opportunities both for securing funding to jointly develop it with other industry players, integrating with other platforms, or creating a separate spin-off in the future. On a daily basis, you will work closely with Danish AM Hub’s leadership and our product owner for the CO2e calculator, building on our experience and network within the Danish industry.

Your key tasks will include:

- Establishing the market potential and identifying user needs so we can develop our front end and provide the most valuable calculations and scenarios

- Scaling – prioritizing processes and materials to be added to the calculator

- Orchestrating the advisors and suppliers required to further build and maintain the platform

- Exploring opportunities for integration with e.g. manufacturers or other platforms

- Setting up a scalable framework for further software development and material additions, e.g. from material producers

- Contributing to applications for innovation/development funding

You will be based in Valby and visit SMEs and larger manufacturers across Denmark, as well as abroad when needed. The role is newly established, and you will have the opportunity to shape it along the way. There is also the possibility of a co-founder role in a scenario where we create an independent company together.

Your profile

You are focused and have a strong sense of prioritization, enabling you to drive and develop the calculator to the benefit of Danish industry – especially small and medium-sized enterprises, but also larger manufacturers.

Ideally, you meet many of the following criteria:

- 5-6 years of experience from a software company, start-up, or consultancy, where you have had direct responsibility for digital development and/or growth strategy

- Understanding of software development and scaling, as well as SaaS principles

- Experience with manufacturing companies and an understanding of product development and production processes

- At least a basic understanding of sustainability dynamics and LCA principles

- A relevant education, e.g. within software development, production technology, strategy, innovation, or similar. Your specific education is less important than your experience.

It is not a requirement that you have prior knowledge of AM technology, but experience with advanced manufacturing and familiarity with the Danish industry will be an advantage, just as speaking Danish is not a requirement but will be an asset for you.

About Dansk AM Hub

Danish AM Hub is Denmark’s national focal point for additive manufacturing (AM). We were initiated and developed by Industriens Fond and in 2025 received significant funding for the next four years.

We are a team of 10 employees with offices in Valby, Herning (AM-Lab Vest), and now also Frederikssund (AM-Lab Øst), where together with DTU and local partners we will create new solutions with metal 3D printing. We work fast and competently in a broad network with both national and global outreach.

We offer a flexible working environment, health insurance, pension scheme, and lunch arrangement.

Application

Send your CV and a few lines about which of our needs you best match to jtc@am-hub.dk, marked ‘Head of digital’. Please keep it short, it is mainly to get a sense of the direction the team would go with you in this role.

If you have questions, please contact Jimmi Christensen, head of program and development, at +45 5221 6078.

Applications will be reviewed on an ongoing basis.

Application deadline: 29th October 2025

Start date: As soon as possible

We look forward to hearing from you.

EuroSkills: Innovation kræver suveræne Skills

Innovation kræver suveræne Skills

Fremtidens teknologiske gennembrud afhænger af stærke faglige kompetencer. Derfor skal vi bakke op om de mange unge, som kæmper om medaljerne til EuroSkills i Herning.

I september går startskuddet til EuroSkills i Herning.

Europas skarpeste lærlinge mødes for at dyste om, hvem der er bedst til at bygge vægge, lægge gulve, installere rør og et væld af andre fascinerende færdigheder.

Der bliver gået til den, og som gæst er det sjovt at se, hvor professionelle, kreative og krævende håndværksuddannelserne er.

I vores digitale tidsalder kan vi let glemme, hvor essentielt håndværket er for vores samfund.

Vi kan ikke få nye veje, skoler og hospitaler, hvis ikke vi har dygtige håndværkere. Det er de fleste nok med på. Men det stikker meget dybere end det.

Vores evne til innovation er dyb afhængig af, at vi har nogle dygtige folk, der mestrer deres fag til fingerspidserne.

Der sker nemlig noget magisk, når hænder og hoved mødes. Når du arbejder med et fag i dybden, kan du også se, hvor potentialet er for forbedring og gøre noget ved det. Og det er vi verdensmestre i herhjemme.

I Danmark er vi gode til at lytte til vores håndværkere. Vi har tradition for et fladt hierarki og et fabriksgulv, hvor der ikke er langt fra tanke til handling. Manden bag maskinen kan stå med fabrikslederen, vende produktet i hænderne og åbent og ærligt diskutere problemer og komme med løsninger.

Den bedste idé vinder uanset rang, og vi går fra luftige ideer til konkret output.

Denne flade hierarkiske struktur ude på virksomhederne skaber enestående forudsætninger for innovation og giver os klare konkurrencefordele i forhold til resten af verden.

Ja, Danmark er faktisk på en fornem 4. plads i den netop offentliggjorte World Competitiveness Ranking i år. Vi ligger lige efter lande som Singapore og Schweiz – ikke mindst takket være vores nysgerrige håndværkere.

Det er dem, som står bag de nye maskiner, introducerer de nye materialer og ændrer designet til de nye løsninger, som bringer os i front.

Uden dygtige håndværkere kommer fornyelsen ikke. Så hænger vi fast i gamle teknologier, som ikke kan løse morgendagens problemer. Så misser vi måske den revolution, der lige netop nu sker indenfor 3D-print, som tager flere og flere industrier med storm. 3D-print har nemlig nogle helt unikke egenskaber i en digital fremtid, hvor vi skal spare på ressourcerne.

I 3D-print bliver produkterne fremstillet ved at printe lag for lag. Det sparer store mængder materialer, mandetimer og CO2 udledninger. Samfundsgevinsterne er enorme, hvis vi får rullet teknologien ud. Og der er helt sikkert noget at komme efter i byggeriet, hvor lagerhaller, huse og skoler allerede nu kan printes på måneder fremfor år.

Men det kræver, at der er dygtige og nysgerrige håndværkere, som tager teknologien til sig, udvikler den og tilpasser den til deres fag.

Derfor skal vi have flere til at vælge håndværket som karrierevej, så vi kan bevare vores unikke position. Men det er ikke nok at have dygtige lærlinge.

Mindst lige så vigtigt er det at have mestre, som bakker op om de unge talenter og opfordrer dem til at søge ny viden, om det så er i værkstedet, på skolebænken eller på Tik Tok.

Og så er vi tilbage til EuroSkills.

For alle de dygtige lærlinge har en ting til fælles: En dygtig og engageret mester, som bakker op om de unges passion, giver dem lyst til at lære og rum til at udvikle sig.

Det giver Skills for livet.

Tex2AM: Nyt dansk projekt vil forvandle tekstilaffald til 3D-print

Tex2AM: Nyt dansk projekt vil forvandle tekstilaffald til 3D-print

Et nyt dansk udviklingsprojekt skal undersøge, om vanskeligt genanvendeligt tekstilaffald kan få nyt liv som 3D-printmateriale. Projektet, der går under navnet Tex2AM, samler partnere fra både erhvervsliv og forskning i et fælles mål om at skabe mere bæredygtige produktionsformer og mindske mængden af tekstilaffald i Danmark og Europa.

Hver europæer bruger i gennemsnit 19 kg tøj, sko og husholdningstekstiler om året, men kun 2,3 kg – svarende til ca. 12 procent – bliver faktisk genanvendt. Resten bliver brændt, deponeret eller sendt til udlandet – og det er et stort problem for både klima og miljø. Men hvad nu hvis det affald kunne blive til noget nyt?

Det skal projektet Tex2AM forsøge at finde svar på. Gennem en avanceret termomekanisk proces vil projektet undersøge, om tekstilaffald med højt indhold af polyester – som ellers er svært at genanvende – kan omdannes til plastbaseret filament til FDM-baseret 3D-print. Processen indebærer bl.a. mekanisk forbehandling og ekstrudering, hvor fibrene nedbrydes, renses og omdannes til et nyt kompositmateriale med de rette tekniske egenskaber til industriel additiv fremstilling.

Målet er at udvikle et genanvendt filament, der matcher eller supplerer eksisterende plastmaterialer med hensyn til styrke, flow-egenskaber og printbarhed, og som samtidig kan integreres i eksisterende produktionsopsætninger. Lykkes det, vil det kunne erstatte jomfruelig plast i industrielle produktioner og dermed give tekstilaffald et helt nyt liv.

Bag projektet står et stærkt dansk konsortium bestående af Dansk AM Hub, DTU og virksomhederne NewRetex, Eldan, Nordic Extrusion og MDT – med støtte fra Trace og Innovationsfonden.

“Vi ser et kæmpe potentiale i at tænke tekstilaffald som en værdifuld ressource. Med Tex2AM kan vi både reducere affaldsmængderne, mindske behovet for ny plast og samtidig styrke lokal, cirkulær produktion i Danmark. Det er præcis den type projekter, vi har brug for, hvis vi skal gøre den grønne omstilling konkret og anvendelig for dansk industri,” siger Frank Rosengreen Lorenzen, direktør i Dansk AM Hub.

Fra affald til innovation

Projektet løber frem til marts 2027 og har som ambition ikke blot at udvikle et nyt materiale – men også at finde konkrete anvendelser i industrien og udvikle en forretningsmodel, der gør det attraktivt for danske virksomheder at bruge det.

For at sikre industriel relevans vil projektet inddrage input fra produktionsvirksomheder til at identificere applikationer, hvor materialet kan erstatte eksisterende plasttyper – f.eks. i komponentproduktion, prototyping eller specialiseret montageudstyr. Samtidig skal der testes forskellige filamentdiametre, udskillelsesmetoder og additiver, for at forbedre stabilitet og ydeevne i printprocessen.

“Der findes et stort, uforløst potentiale i at omdanne komplekst tekstilaffald til højværdimaterialer til 3D-print. Med Tex2AM undersøger vi, hvordan man gennem mekanisk forbehandling og ekstrudering kan udvikle et plastbaseret kompositmateriale, der både genbruger affald og lever op til de tekniske krav, som industriel, additiv fremstilling stiller. Det er en vigtig bro mellem affaldsressourcer og cirkulær, digital produktion,” siger Senior Researcher, Venkata K. Nadimpalli, DTU Construct.

Om Tex2AM

Tex2AM (Textile to Additive Manufacturing) er et dansk udviklingsprojekt, der undersøger mulighederne for at omdanne polyesterholdigt tekstilaffald til plastbaseret filament til 3D-print. Projektet ledes af Dansk AM Hub i samarbejde med DTU, NewRetex, Eldan, Nordic Extrusion og MDT. Tex2AM er støttet og finansieret af Trace og Innovationsfonden og løber frem til marts 2027.

Læs mere om projektet her.