Brian Garret: “3D printing is at the intersection between the digital world and the physical world“

The start-up company, 3D Hubs, is the Airbnb of the AM industry. Over time, the company has evolved from a network of hobbyists to a platform for professionals. The transformation has cost the goodwill of early fans but was necessary for the survival of the company, says co-founder Brian Garret, who believes the future looks bright for entrepreneurs.

By Erik Holm

“I’ll just find a quiet spot and grab a cup of coffee. Call you back in two minutes.”

Brian Garret has found a spare moment in a busy day. There aren’t enough hours in the day for the co-founder and CPO of the 3D Hubs start-up company. After a brief dip around 2017, the company has once more gone into turbo-drive. In just six months, 3D Hubs has doubled its number of employees to almost 100 people across five countries, and there is increasing interest in the online platform. From its base in Amsterdam, the company acts as an intermediary between customers and manufacturers of 3D-printed components and CNC-machined components.

“We’ll soon be opening offices in France, Germany and the United Kingdom. So, we’re busy,” says Brian, when he gets back on the phone.

Hooked on 3D printing

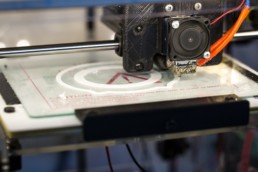

The story of Brian Garret is the story of a Dutch/Canadian product designer who became a successful entrepreneur. In 2003, while Garret was a student at the technical university of Eindhoven, a teacher introduced him to 3D printing. Garret was asked to design a number of products to be printed by the researchers’ working group.

“I was completely blown away when I held the printed parts in my own hands. As a designer, you often move between the digital and physical worlds, and 3D printing exists somewhere in the middle. I was hooked,” remembers Brian Garret.

After his studies, Garret worked for a design company in Amsterdam, where he specialized in applying additive technologies to consumer products. This is where he met Bram de Zwart and the two of them came up with the idea for 3D Hubs soon after. They were inspired by sharing services such as Airbnb and Uber.

“A lot of people had installed printers, but they were scattered and disorganized. At the same time, most customers only made very limited use of these printers, and didn’t want to own one themselves, given the technical know-how it would require. Furthermore, there were many different technologies and the fragmented industry meant there was a market for an online platform to connect customers and printer owners,” says Brian Garret.

The idea brewed for a few years and in 2013, while they were both working for 3D Systems, they started their own company, 3D Hubs. The company was an overnight global success, thanks in great part to a very committed 3D printing community. In 2016, when the network was at its peak, 3D Hubs had 30,000 locations in 160 countries – more than McDonalds. Then the founders changed direction.

“We had customers ordering printed components many times a year and who therefore wanted more continuity in production. Therefore we began to professionalise the network and only allow certified companies to print with us,” explains Garret.

For those who joined the original network, this change broke with the original idea behind 3D Hubs. Angry and disappointed comments flooded both the internet and the inboxes of the founders, who spent hours trying to respond to as many as possible. Today, Brian Garret is convinced that they did the right thing, but the transition was hard, he admits.

“We were a company with professional investors and customers. We wanted to make sure that the company would survive so we chose in a more serious direction. I don’t think we’d exist today if we hadn’t professionalised the network. Now we’re a production platform for the industry, and we still have many members in the network who have been with us since the beginning,” says Garret.

Three million components

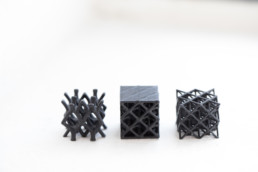

3D Hubs now provides services to a wide variety of companies, particularly within the motor industry, aerospace, healthcare and consumer electronics. As Garret says, anyone who produces physical products is potentially in their target group. The basic idea is that customers should not be able to tell whether a component is printed in the US, Germany or China.

Since the transformation, the company has added CNC machining, injection moulding and sheet metal fabrication in a ready-made concept called “Fulfilled by 3D Hubs”, launched in 2017. Thanks to new software supported by machine learning, artificial intelligence and experience gained by brokering the production of more than three million printed components, customers can now receive a price estimate within seconds.

“There’s still too much paperwork and too many manual tasks in connection with production. We’ve automated a large part of the production process. You can now upload components and be advised on the best production technology to use, as well as receive feedback on your design. We’re digitalising this part of the process and have great expectations for this development,” says Brian Garret. He continues:

“As a society, we’re moving away from the days of companies having large stocks of different components. In the future, we’ll see that companies have small stocks with only a few units, and they will print more based on demand. This will also allow for ongoing adjustments to designs of otherwise finalised products, for example in the car industry.

Good times for entrepreneurs

In the beginning, the two founders benefited from the hype surrounding additive manufacturing. So far, 3D Hubs has received over USD 30 million in venture capital. This has been the exciting part of being an entrepreneur, says Garret.

Despite his own success, he is even more optimistic about the opportunities for other entrepreneurs working with additive manufacturing. Today, much larger sums are being invested in the whole value chain, from software to hardware, and from materials to services. Entrepreneurs looking to start a business within AM will have a pretty good hand when it comes to technology and raising capital, he believes:

“Additive manufacturing is still in its infancy. The industry will continue to grow over the next 10 years as the technology matures and more and more people begin using additive manufacturing. Mass production will become increasingly common, as we’re already experiencing with 3D components in running shoes and glasses. True innovation in additive manufacturing is happening right now and in all areas, from software to services.

If Brian Garret, as a successful entrepreneur, were to give advice to other entrepreneurs, it would be to think globally from the start, find a niche, a specific product or service and cultivate a community.

“You can’t cast your net too wide because you don’t have the resources in the beginning. Start with 100 super pleased customers who will spread the word, and soon that number could grow to the thousands. Keep your focus and become the best within your niche. It’ll hard for others to copy you, once you’ve gotten a firm grip.”

Brian Garret, born in 1985, is the co-founder and CPO of 3D Hubs in Amsterdam. He established the company in 2013 with Bram de Zwart. The company is an online link between producers and consumers of various production tasks. 3D Hubs is headquartered in Amsterdam, with offices in both Chicago and Paris. 3D Hubs will soon open offices in Germany and the UK. Brian has a Master of Science from Eindhoven University of Technology. He previously worked with 3D printing as a designer. Brian lives with his girlfriend in Amsterdam.