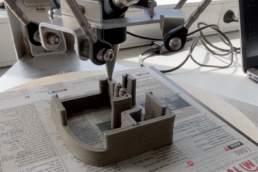

3D Printing + Injection Molding: COVID-19 Collaboration Scales Up Within A Week

![MiMo mask adaptors made using KRAIBURG TM7 MED grade [Image: AddiFab]](https://images.squarespace-cdn.com/content/v1/509c281de4b0cd18c7335aab/1586535351362-1WTZQPPXBOQM65BJNSQA/ke17ZwdGBToddI8pDm48kL3VKmwKI3leYB51VJjLFB8UqsxRUqqbr1mOJYKfIPR7LoDQ9mXPOjoJoqy81S2I8N_N4V1vUb5AoIIIbLZhVYxCRW4BPu10St3TBAUQYVKcgK5SGg9Ovb1yloBBOHcruw_mYLfAhRzzgArFCB07Dw0L8n4JypuoE5Tg6Wg5Oyvs/IMG_20200407_153807_1.JPG)

MiMo mask adaptors made using KRAIBURG TM7 MED grade [Image: AddiFab]

Scaling up production to help in the fight against pandemic poses certain challenges — that are increasingly possible to overcome.

Most uses of 3D printing in addressing COVID-19 are quick-response, stop-gap supply chain needs for personal protective equipment (PPE) and other need-it-now goods. It is generally acknowledged that these first response measures are just that: a first response, typically the vanguard of full-scale efforts realized by more traditional mass production manufacturing like injection molding.

A new joint effort, though, is seeing the benefit of 3D printing combined with injection molding to have reached a scale solution in six days.

Read the full story: 3D Printing + Injection Molding: COVID-19 Collaboration Scales Up Within A Week

Related Posts

10/07/2025

Dansk AM Hub udvider med nyt teknologilaboratorium i Frederikssund

Danmark har fået en ny platform for…

19/06/2025

Print og byg: Kan 3D-print i stor skala blive et nyt værktøj for byggebranchen?

Mindre materialeforbrug, lavere CO2…

17/06/2025

AM Summit vender tilbage i 2025 i nyt format med fokus på små og mellemstore virksomheder

Efter et succesfuldt AM Summit 2024…

05/03/2025

3DCP sætter betonprint på skoleskemaet sammen med Herningsholm Erhvervsskole

I et undervisningsforløb mellem 3DCP…

16/01/2025

Med 3D-print og bæredygtighed i fokus: KK Wind Solutions baner vejen for fremtidens vindmøller

KK Wind Solutions har udviklet en ny…

18/11/2024

PERFI Prints a Hearing Aid in Seconds – Could Transform the Entire Industry

The startup company won a pitch…

30/10/2024

AM Summit skabte et kreativt rum mellem udstillere og deltagere

Paneldebat om verdens hurtigste cykel…

19/09/2024

Derfor er industriel 3D-print en gevinst for historisk byggeri

Matteo Baldassari fra virksomheden…

19/08/2024

Space Challenge: Design the Future of Space Exploration

Dreaming of space? Now’s your chance to…

12/12/2023

Redesignet kølesystem laver varmt vand til fjernvarmen

Heatflow, som laver kølesystemer til…

29/09/2023

Danmarks første additive manufacturing (3dprint) pris uddeles til spirende startup, der har printet en børnehave i Ukraine

Verdens største AM-messe Formnext har…

27/06/2023

Danmark udnævnes til kernepartner for verdens største 3D print messe

Verdens største AM-messe Formnext har…

13/06/2023

AM Summit 2023: Presenting this year’s strong programme

40+ speakers. 45+ exhibitors. 450+…

12/06/2023

Kan man designe en væg med mindre materiale og samme bæreevne?

Apex Wall er et bemærkelsesværdigt…

12/06/2023

Helt grøn på klimakommunikation? Sådan undgår du faldgruberne

Vil du undgå greenwashing? Så har…

09/06/2023

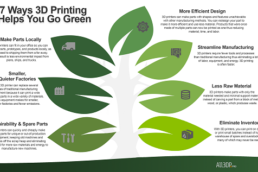

Er Additive Manufacturing løsningen på vores forsynings- sikkerheds- og klimakrise?

Direktør Frank Rosengreen Lorenzens…

30/05/2023

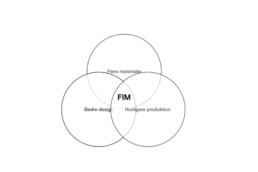

Nyt projekt: 3D print skal kunne følge med sprøjtestøbning

AM Farm: Nyt projekt vil sikre, at en…

03/05/2023

Dansk AM Hub mødte tusindvis af nysgerrige på årets VTM

I april var Dansk AM Hub blandt de 116…

28/04/2023

Wohlers Rapport 2023 afslører fortsat tocifret vækst i AM industrien

Wohlers Associates, drevet af ASTM…

20/04/2023

Mød os på VTM Summit og bliv klogere på 3D print i metalindustrien

Mød os på VTM Summit 2023 fra 25.-28.…

14/04/2023

Se billeder fra vores AM Talenters besøg hos The LEGO Group

Sammen med 20 talenter fra vores AM…

30/03/2023

Lær om AM teknologiens fulde potentiale på nyt dansk masterfag

Fra foråret 2023 udbydes faget Value…

24/03/2023

6. kl. skifter klasseværelset ud med et besøg i Damvigs 3D print-produktion

I marts var 18 elever fra 6. klasse på…

24/03/2023

Vær med til at accelerere den cirkulære omstilling på LOOP Forum

Nordens førende event om cirkulær…

22/03/2023

Debat: Lad fremtidens teknologi genopbygge Ukraine

AM rummer et stort potentiale både ift.…

20/03/2023

Prototal Damvig cases: Højere kvalitet, funktionalitet og reduceret time to market

Prototal Damvig har på det seneste…

21/02/2023

Join other AM Talents for a behind-the-scenes visit to the LEGO Group’s AM Facilities

Join other AM Talents for a…

07/02/2023

AM Magazine 2023: Additive Manufacturing & fire konkrete trin til en grønnere produktion

I AM Magazine 2023 får du fire konkrete…

07/02/2023

New report: Sustainable Manufacturing of the Future: The Role of Additive Manufacturing

This report gathers our approach to…

30/01/2023

Chatbot leverer lynhurtigt SWOT-analyse af 3D print-teknologiens potentiale for at skabe mere bæredygtig produktion

Dansk AM Hub er hoppet med på trenden…

16/01/2023

Ny Roland Berger-rapport: Hvor bæredygtigt er AM egentlig?

En ny Roland Berger rapport tager et…

12/01/2023

Nyt industrifællesskab hjælper danske virksomheder med at 3D printe i metal

Nu går en lang række aktører sammen i…

12/01/2023

Danish AM Hub launches Report on Additive Manufacturing in Crisis Response

Danish AM Hub, in cooperation with…

05/01/2023

Med AM-teknologi vil Wohn bygge billige og mere bæredygtige Tiny Houses

WOHN er en dansk startup med en vision…

04/01/2023

Dansk genanvendt metalpulver revolutionerer 3D metalprint industrien

Nordic Metals indsamler maskin- og…

13/12/2022

Lostboyslab demonstrerer potentialet ved AM i en cirkulær økonomi

Lostboyslab har skabt et maker lab,…

12/12/2022

AM Power Insights: Sustainability of Metal Additive Manufacturing

I en ny rapport kortlægger AM Power det…

07/12/2022

Dansk AM Hub lancerer karriereplatform for nye AM-talenter

I det nye år vil Dansk AM Hub lancere…

01/12/2022

Dansk AM Hub kursus: Hvordan kan vi skabe værdi gennem Additive Manufacturing?

Dansk AM Hub udbyder et nyt kursus, der…

01/12/2022

Nyt masterkursus uddanner virksomheder i at udnytte 3D print-teknologien

Dansk AM Hub har i samarbejde med SDU…

16/11/2022

Webinar: Bliv klogere på potentialerne ved additive manufacturing

Se dette webinar, der kan gøre dig…

12/10/2022

AM Summit 2022: See pictures from this year’s exhibitors

AM Summit 2022: See pictures from this…

11/10/2022

3D printede designs sætter virksomheders produkter på slankekur

I DfAM-forløbet har 10 ud af 11…

05/10/2022

Hver anden virksomhed fortsætter med AM-teknologien efter 3D print-hybrid-forløb

Når først virksomheder har oplevet de…

05/10/2022

Mød os på Digital Tech Summit – og få 40 % rabat på din billet

Dansk AM Hub taler på Digital Tech…

04/10/2022

Maker-program inspirerer virksomheder til optimerede design- og produktionsmetoder

I 2022 har Dansk AM Hub for første gang…

04/10/2022

AM Summit 2022 breakout session: Learn from Danish AM Experts

Read more from AM Summit 2022 breakout…

04/10/2022

AM Summit 2022 breakout session: Meet the Women in 3D Printing

Read more from Women in 3D Printing -…

27/09/2022

AM Summit 2022 breakout session: Sustainable Materials

Read more from Sustainable Materials -…

14/09/2022

AM Summit 2022 breakout session: 3D Printing Sustainable Cities

Read more from 3D Printing Sustainable…

14/09/2022

AM Summit 2022 breakout session: Changing Paradigms

Read more from Changing Paradigms - one…

13/09/2022

More people than ever gather for sustainable 3D print conference

AM Summit 2022 marked another…

13/09/2022

Flere end nogensinde samles til grøn 3D print konference

AM Summit 2022 slog igen i år rekord…

05/09/2022

3D print konference nytegner byggeri med den bæredygtige blyant

Additive manufacturing (AM) og 3D…

18/08/2022

Seminar gør dig klogere på avanceret og bæredygtig produktion

Udenrigsministeriet afholder i…

18/08/2022

Konference kalder kvinderne til 3D print-produktionsgulvene

Der er ikke mange kvinder repræsenteret…

18/08/2022

3D print konference: Materialer gør afgørende forskel for bæredygtig produktion

Vi skal have vores samlede…

04/08/2022

Live fra AM Summit 2022: Guns N’ Roses rocker på en 3D printet guitar

AM Summit 2022 inviterer til koncert…

13/07/2022

Deltag i Design for Additive Manufacturing (DfAM) – afslutningsevent

Bliv introduceret til DfAM-projektet og…

29/06/2022

Studerende og virksomheder står allerede i kø til ny 3D print-uddannelse

Efter sommerferien begynder det første…

16/06/2022

3D print-konference udfordrer, hvordan et produkt designes, udvikles og produceres

AM Summit 2022 sætter fokus på, hvordan…

14/06/2022

Grøn Tech-tillæg: Sådan kan 3D print hjælpe dansk produktion i den grønne førertrøje

I Grøn Tech-tillægget i Berlingske og…

13/06/2022

Dansk AM Hub taler bæredygtig dansk produktion på AMGTA Summit

Med indførelse af en ny dansk…

30/05/2022

Stor fremgang i 3D print rykker konference til større lokaler

AM og 3D print har haft vokseværk de…

25/05/2022

Produktionsvirksomheder printer sig til bedre produkter – kom og hør hvordan

Vær med når Industriens Fond byder på…

12/05/2022

Prototal Damvig indfører ny 3D print teknologi til Danmark

Som de første i Danmark - og med den…

11/05/2022

WEF Rapport sammenligner 13 AM Hubs globalt: Fremhæver dansk bæredygtigt fokus

Læs den nyeste rapport om Global…

29/04/2022

McKinsey: Industrien for medicinsk udstyr har stor succes med AM teknologien

Industrien for medicinsk udstyr har i…

13/04/2022

LOOP: Her er løsningen på stigende mængder affald og øget ressourceforbrug

LOOP bringer viden, erfaringer,…

06/04/2022

Nye indsatser kan afhjælpe mangel på kvalificeret arbejdskraft

Flere små og mellemstore danske…

29/03/2022

Wohlers rapport 2022 viser stærk vækst i AM-industrien

Wohlers Report is an industry-leading…

28/03/2022

Portræt: Steffen skal inspirere dig til at printe i metal

Læs et portræt af Dansk AM Hubs CTO…

25/03/2022

More and more Danish manufacturing companies use AM technology

In 2021, more than ever Danish…

10/03/2022

Danskere 3D printer årepresser til sårede i Ukraine

Det danske 3D print-miljø samles nu om…

09/03/2022

Danske virksomheder skal designe bedre produkter med 3D teknologi

DfAM er vores nye innovationsforløb,…

02/03/2022

A Guidebook for the Adoption of Additive Manufacturing in Operations

A new guidebook aims to provide…

04/02/2022

Danske virksomheder griber gratis mulighed for at prøve 3D print

Flere danske virksomheder har i 2021…

13/12/2021

Investorer og iværksættere viste endnu en gang AMs store potentiale

AM Venture Day handler om at bringe…

01/12/2021

Venture Day 2021: Dansk AM Hub matcher iværksættere og investorer

AM Venture Day handler om at bringe…

18/11/2021

Vinderne af den landsdækkende 3D-print-konkurrence er nu fundet

Simon og Emil fra Herningsholm…

28/10/2021

Dansk AM-teknologi printer huse i Afrika mere bæredygtigt

Danske COBOD International har nu 3D…

19/10/2021

Debat: Forsyningskrisen skal få os til at gentænke produktionssystemet

Forsyningskrisen afslører behovet for…

18/09/2021

Watch – or rewatch! – all of the presentations from AM Summit 2021

The presentations from AM Summit 2021…

17/09/2021

Webinar: Analyse viser, at Additive Manufacturing sparer penge, tid og CO2

LCA rapporten udearbejdet efter vores…

15/09/2021

Wikifactory og Dansk AM Hub: Danmark skal være midtpunkt for bæredygtig produktion

Danmarks AM-miljø er blandt årsagerne…

27/08/2021

Vil du deltage i et forløb om prøvelse af 3D printede fiksturer?

I efteråret 2021 tilbydes fem…

25/08/2021

Nordiske virksomheder vil (be)vise vejen i den grønne omstilling via Additive Manufacturing

Med en række partnere vil Dansk AM Hub…

25/05/2021

Sådan skaber vi dansk bæredygtighed gennem Additive Manufacturing

Direktør i Dansk AM Hub, Frank…

19/05/2021

40 millioner skal styrke dansk bæredygtig produktion

Industriens Fond geninvesterer i Dansk…

07/05/2021

Protected: Dansk AM Hub indgår samarbejde med 3D Eksperten

Dansk AM Hub indgår samarbejde med 3D…

18/03/2021

Endnu et vellykket Hybrid-forløb: Virksomheder forbedrer produkter, mens de sparer penge, tid og bliver mere bæredygtige

Læs her om fem virksomheder, som…

17/03/2021

Ny rapport viser global vækst for 3D print trods pandemi

Wohlers report giver en status på AM…

15/03/2021

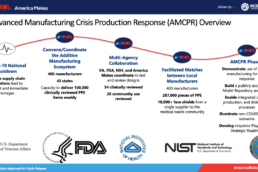

AM udgør et stærkt våben i America Makes’ kamp mod COVID19 – og fremtidige kriser

Læs om hvordan America Makes spillede…

12/03/2021

Webinar-optagelse: AM – Leading the Rebound of American Manufacturing

How do we use Additive Manufacturing…

23/02/2021

Webinar: AM – Leading the Rebound of American Manufacturing

I dette webinar hører vi amerikanske…

11/02/2021

Webinar: Genanvendt plast og 3D print – effektiv grøn omstilling

Genanvendt plast og 3D print er temaet…

10/02/2021

Norden samles for at styrke et fælles fokus på 3D print

Sammen med Alfred Nobel Science Park,…

03/02/2021

Wikifactory is moving its global headquarters from Hong Kong to Denmark

Wikifactory is moving its global…

01/02/2021

Dansk AM Rapport 2021: Potentiale til en bæredygtig fremtid

Dansk AM Rapport 2021 - bliv klogere på…

12/01/2021

Dit juridiske ansvar i markedsføringen af 3D-teknologiens bæredygtige potentiale

Accura advokater har endnu engang…

08/12/2020

Nyt europæisk projekt etablerer produktionsberedskab til fremtidige sundhedskriser

Nyt fælleseuropæisk projekt skal sikre…

24/11/2020

Accuras juridiske anbefalinger til dig, der bruger 3D print

Accura advokater har samlet en række…

22/10/2020

Additive Manufacturer Green Trade Association Announces New Members

Danish AM Hub becomes part of a global…

28/08/2020

Vær bevidst om dit juridske ansvar ved brug af 3D print

Accura advokater har samlet en række…

04/06/2020

The Impact of COVID-19 on the Future of Advanced Manufacturing and Production

Insights from the World Economic…

26/05/2020

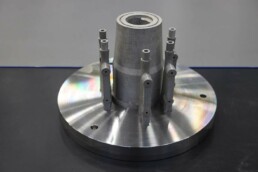

Terma reducerer materialeforbrug og produktionstid markant med AM

Hidtil har Terma A/S haft et højt…

07/01/2020

Svenske Prototal AB køber den danske 3D-print virksomhed Damvig A/S

Damvig A/S har indtil salget været ejet…

05/12/2019

Danish AM Hub as winner of German Design Award 2020

In the fall of 2019, Danish AM Hub won…

24/09/2019

3D Print kommer til at revolutionere implantat-markedet

Particle3D har med sloganet "We print…

12/06/2019

Dansk AM Hub vil hente udenlandsk kapital til danske start-up virksomheder inden for 3D print

Et nyt initiativ fra Dansk AM Hub skal…

14/01/2019

40 AM eksperter giver deres bud på udviklingen i 2019

Michael Petch fra medievirksomheden 3D…

08/01/2019

The potential in Additive Manufacturing

07/12/2018

Additive Manufacturing er drivkraften for bilindustriens fremtid

Forbes artikel skrevet af Sarah Goehrke…

27/11/2018

Addifab fordobler omsætningen det første år med 3D print og sprøjtestøbning

Sidste år vandt AddiFab i Jyllinge…

10/09/2018

Dansk AM Hub er dansk anker på nordisk samarbejde om 3D print

Det er første gang der samles et…

07/06/2018

Danske virksomheders konkurrenceevne skal styrkes med 3D print

3D print og Additive Manufacturing er…

06/06/2018

Monoqool var halvvejs i skifteretten – en 3D-printer forhindrede likvidering og grundlagde en millionforretning

Danske virksomheder kan lære meget af…

06/06/2018

Danske virksomheder sakker bagud i milliardstort 3D-kapløb

Med 46 mio. kr. i ryggen skal Dansk AM…

21/03/2018

Siemens investerer stort i 3D print

30/01/2018

Regeringens nye digitale vækstinitiativ vil skabe synergi med AM Hub

I forlængelse af mødet i…

23/01/2018

Huismans 3D printede kran-krog testet til bæreevne på 80.000 kg

Huisman, en verdensomspændende…

22/01/2018

Harvard forskningsprojekt udvikler roterende 3D print metode, der producerer som naturen gør det

Kompositmaterialer, der findes…