Changing Paradigms

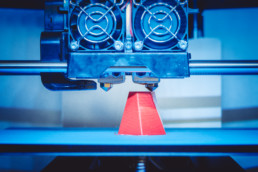

AM Summit 2022 breakout session: Changing Paradigms placed focus on how Additive Manufacturing has and will impact different manufacturing industries. The session brought together industry leaders using AM as an industry disrupter to drive forward a radical new way of designing, innovating, and producing products and components.

The breakout session was moderated by Tim Frank Andersen, CEO and Co-Founder, Liveshopper. The industry leader participants in the panel included:

- Andrew Lamb, Innovation Lead – Global, Field Ready

- Stefan Larsson, Founder, Maker and Entrepreneur, Lostboyslab and Whatt.io

- Adam R. Pawloski, VP Manufacturing Solutions, Stratasys

- Federica Chinese, Sales Manager EMEA, Nano Dimension

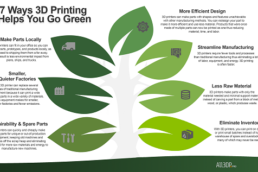

Although in recent years AM technology is increasingly being adopted by the manufacturing industry, and their examples where it has disrupted the industry and led to new ways of designing and manufacturing products, the panellists agree that there is still work to be done for AM to reach the so-called ‘Spotify moment’. One of the ways to facilitate this move towards changing paradigms is for industry leaders to share their good examples. Especially two issues were discussed more at length, sustainable materials and distributed manufacturing.

Sustainable materials and the issue of cost

One of the panellists, from Lostboyslab, use 90 percent recycled materials in their 3D printed products. The recycled material is generally more expensive than virgin material. However, they experience that their customers are willing to pay extra for sustainability and the “story” of the material. Recycled fishnets collected in Indonesia, where local fishermen are being paid for collecting waste from the ocean, is one example of the recycled material being used. This addresses one of the biggest environmental challenges of removing waste from the oceans while securing an income for local fishermen.

For others the costs of recycled materials, but also in general the costs of 3D printing compared to other manufacturing methods, remains a barrier for more widespread use of AM by the manufacturing industry. In order to overcome this barrier, stronger collaboration in the AM ecosystem is needed. A point that is highlighted in connection with this is the need to produce and share data based on early AM adopters to demonstrate that industry can adopt AM with low risk.

Unleashed potential of distributed manufacturing

The potentials of distributed manufacturing were discussed in connection with a question to the panel on what it takes for additive manufacturing to reach the ‘Spotify moment’. This involves a need to change business models and create distributed networks of partners or satellites to 3D print locally. For Field Made, a humanitarian organisation transforming aid logistics by manufacturing supplies in the field, there is an imminent need to map 3D printers across the developing countries of the world. In time this could allow the possibility to contract private makers and companies around the world to deliver individually on one single large order for 3D printed devices. For this to become reality, it is also necessary to address regulatory implications related to quality control processes in distributed manufacturing.

Related Posts

12/12/2023

Redesignet kølesystem laver varmt vand til fjernvarmen

Heatflow, som laver kølesystemer til…

29/09/2023

Danmarks første additive manufacturing (3dprint) pris uddeles til spirende startup, der har printet en børnehave i Ukraine

Verdens største AM-messe Formnext har…

27/06/2023

Danmark udnævnes til kernepartner for verdens største 3D print messe

Verdens største AM-messe Formnext har…

13/06/2023

AM Summit 2023: Presenting this year’s strong programme

40+ speakers. 45+ exhibitors. 450+…

12/06/2023

Kan man designe en væg med mindre materiale og samme bæreevne?

Apex Wall er et bemærkelsesværdigt…

12/06/2023

Helt grøn på klimakommunikation? Sådan undgår du faldgruberne

Vil du undgå greenwashing? Så har…

09/06/2023

Er Additive Manufacturing løsningen på vores forsynings- sikkerheds- og klimakrise?

Direktør Frank Rosengreen Lorenzens…

30/05/2023

Nyt projekt: 3D print skal kunne følge med sprøjtestøbning

AM Farm: Nyt projekt vil sikre, at en…

03/05/2023

Dansk AM Hub mødte tusindvis af nysgerrige på årets VTM

I april var Dansk AM Hub blandt de 116…

28/04/2023

Wohlers Rapport 2023 afslører fortsat tocifret vækst i AM industrien

Wohlers Associates, drevet af ASTM…

20/04/2023

Mød os på VTM Summit og bliv klogere på 3D print i metalindustrien

Mød os på VTM Summit 2023 fra 25.-28.…

14/04/2023

Se billeder fra vores AM Talenters besøg hos The LEGO Group

Sammen med 20 talenter fra vores AM…

30/03/2023

Lær om AM teknologiens fulde potentiale på nyt dansk masterfag

Fra foråret 2023 udbydes faget Value…

24/03/2023

6. kl. skifter klasseværelset ud med et besøg i Damvigs 3D print-produktion

I marts var 18 elever fra 6. klasse på…

24/03/2023

Vær med til at accelerere den cirkulære omstilling på LOOP Forum

Nordens førende event om cirkulær…

22/03/2023

Debat: Lad fremtidens teknologi genopbygge Ukraine

AM rummer et stort potentiale både ift.…

20/03/2023

Prototal Damvig cases: Højere kvalitet, funktionalitet og reduceret time to market

Prototal Damvig har på det seneste…

21/02/2023

Join other AM Talents for a behind-the-scenes visit to the LEGO Group’s AM Facilities

Join other AM Talents for a…

07/02/2023

AM Magazine 2023: Additive Manufacturing & fire konkrete trin til en grønnere produktion

I AM Magazine 2023 får du fire konkrete…

07/02/2023

New report: Sustainable Manufacturing of the Future: The Role of Additive Manufacturing

This report gathers our approach to…

30/01/2023

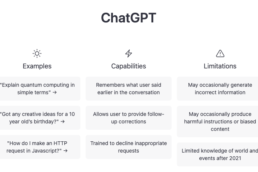

Chatbot leverer lynhurtigt SWOT-analyse af 3D print-teknologiens potentiale for at skabe mere bæredygtig produktion

Dansk AM Hub er hoppet med på trenden…

16/01/2023

Ny Roland Berger-rapport: Hvor bæredygtigt er AM egentlig?

En ny Roland Berger rapport tager et…

12/01/2023

Nyt industrifællesskab hjælper danske virksomheder med at 3D printe i metal

Nu går en lang række aktører sammen i…

12/01/2023

Danish AM Hub launches Report on Additive Manufacturing in Crisis Response

Danish AM Hub, in cooperation with…

05/01/2023

Med AM-teknologi vil Wohn bygge billige og mere bæredygtige Tiny Houses

WOHN er en dansk startup med en vision…

04/01/2023

Dansk genanvendt metalpulver revolutionerer 3D metalprint industrien

Nordic Metals indsamler maskin- og…

13/12/2022

Lostboyslab demonstrerer potentialet ved AM i en cirkulær økonomi

Lostboyslab har skabt et maker lab,…

12/12/2022

AM Power Insights: Sustainability of Metal Additive Manufacturing

I en ny rapport kortlægger AM Power det…

07/12/2022

Dansk AM Hub lancerer karriereplatform for nye AM-talenter

I det nye år vil Dansk AM Hub lancere…

01/12/2022

Dansk AM Hub kursus: Hvordan kan vi skabe værdi gennem Additive Manufacturing?

Dansk AM Hub udbyder et nyt kursus, der…

01/12/2022

Nyt masterkursus uddanner virksomheder i at udnytte 3D print-teknologien

Dansk AM Hub har i samarbejde med SDU…

16/11/2022

Webinar: Bliv klogere på potentialerne ved additive manufacturing

Se dette webinar, der kan gøre dig…

12/10/2022

AM Summit 2022: See pictures from this year’s exhibitors

AM Summit 2022: See pictures from this…

11/10/2022

3D printede designs sætter virksomheders produkter på slankekur

I DfAM-forløbet har 10 ud af 11…

05/10/2022

Hver anden virksomhed fortsætter med AM-teknologien efter 3D print-hybrid-forløb

Når først virksomheder har oplevet de…

05/10/2022

Mød os på Digital Tech Summit – og få 40 % rabat på din billet

Dansk AM Hub taler på Digital Tech…

04/10/2022

Maker-program inspirerer virksomheder til optimerede design- og produktionsmetoder

I 2022 har Dansk AM Hub for første gang…

04/10/2022

AM Summit 2022 breakout session: Learn from Danish AM Experts

Read more from AM Summit 2022 breakout…

04/10/2022

AM Summit 2022 breakout session: Meet the Women in 3D Printing

Read more from Women in 3D Printing -…

27/09/2022

AM Summit 2022 breakout session: Sustainable Materials

Read more from Sustainable Materials -…

14/09/2022

AM Summit 2022 breakout session: 3D Printing Sustainable Cities

Read more from 3D Printing Sustainable…

13/09/2022

More people than ever gather for sustainable 3D print conference

AM Summit 2022 marked another…

13/09/2022

Flere end nogensinde samles til grøn 3D print konference

AM Summit 2022 slog igen i år rekord…

05/09/2022

3D print konference nytegner byggeri med den bæredygtige blyant

Additive manufacturing (AM) og 3D…

18/08/2022

Seminar gør dig klogere på avanceret og bæredygtig produktion

Udenrigsministeriet afholder i…

18/08/2022

Konference kalder kvinderne til 3D print-produktionsgulvene

Der er ikke mange kvinder repræsenteret…

18/08/2022

3D print konference: Materialer gør afgørende forskel for bæredygtig produktion

Vi skal have vores samlede…

04/08/2022

Live fra AM Summit 2022: Guns N’ Roses rocker på en 3D printet guitar

AM Summit 2022 inviterer til koncert…

13/07/2022

Deltag i Design for Additive Manufacturing (DfAM) – afslutningsevent

Bliv introduceret til DfAM-projektet og…

29/06/2022

Studerende og virksomheder står allerede i kø til ny 3D print-uddannelse

Efter sommerferien begynder det første…

16/06/2022

3D print-konference udfordrer, hvordan et produkt designes, udvikles og produceres

AM Summit 2022 sætter fokus på, hvordan…

14/06/2022

Grøn Tech-tillæg: Sådan kan 3D print hjælpe dansk produktion i den grønne førertrøje

I Grøn Tech-tillægget i Berlingske og…

13/06/2022

Dansk AM Hub taler bæredygtig dansk produktion på AMGTA Summit

Med indførelse af en ny dansk…

30/05/2022

Stor fremgang i 3D print rykker konference til større lokaler

AM og 3D print har haft vokseværk de…

25/05/2022

Produktionsvirksomheder printer sig til bedre produkter – kom og hør hvordan

Vær med når Industriens Fond byder på…

12/05/2022

Prototal Damvig indfører ny 3D print teknologi til Danmark

Som de første i Danmark - og med den…

11/05/2022

WEF Rapport sammenligner 13 AM Hubs globalt: Fremhæver dansk bæredygtigt fokus

Læs den nyeste rapport om Global…

29/04/2022

McKinsey: Industrien for medicinsk udstyr har stor succes med AM teknologien

Industrien for medicinsk udstyr har i…

13/04/2022

LOOP: Her er løsningen på stigende mængder affald og øget ressourceforbrug

LOOP bringer viden, erfaringer,…

06/04/2022

Nye indsatser kan afhjælpe mangel på kvalificeret arbejdskraft

Flere små og mellemstore danske…

29/03/2022

Wohlers rapport 2022 viser stærk vækst i AM-industrien

Wohlers Report is an industry-leading…

28/03/2022

Portræt: Steffen skal inspirere dig til at printe i metal

Læs et portræt af Dansk AM Hubs CTO…

25/03/2022

More and more Danish manufacturing companies use AM technology

In 2021, more than ever Danish…

10/03/2022

Danskere 3D printer årepresser til sårede i Ukraine

Det danske 3D print-miljø samles nu om…

09/03/2022

Danske virksomheder skal designe bedre produkter med 3D teknologi

DfAM er vores nye innovationsforløb,…

02/03/2022

A Guidebook for the Adoption of Additive Manufacturing in Operations

A new guidebook aims to provide…

04/02/2022

Danske virksomheder griber gratis mulighed for at prøve 3D print

Flere danske virksomheder har i 2021…

13/12/2021

Investorer og iværksættere viste endnu en gang AMs store potentiale

AM Venture Day handler om at bringe…

01/12/2021

Venture Day 2021: Dansk AM Hub matcher iværksættere og investorer

AM Venture Day handler om at bringe…

18/11/2021

Vinderne af den landsdækkende 3D-print-konkurrence er nu fundet

Simon og Emil fra Herningsholm…

28/10/2021

Dansk AM-teknologi printer huse i Afrika mere bæredygtigt

Danske COBOD International har nu 3D…

19/10/2021

Debat: Forsyningskrisen skal få os til at gentænke produktionssystemet

Forsyningskrisen afslører behovet for…

18/09/2021

Watch – or rewatch! – all of the presentations from AM Summit 2021

The presentations from AM Summit 2021…

17/09/2021

Webinar: Analyse viser, at Additive Manufacturing sparer penge, tid og CO2

LCA rapporten udearbejdet efter vores…

15/09/2021

Wikifactory og Dansk AM Hub: Danmark skal være midtpunkt for bæredygtig produktion

Danmarks AM-miljø er blandt årsagerne…

27/08/2021

Vil du deltage i et forløb om prøvelse af 3D printede fiksturer?

I efteråret 2021 tilbydes fem…

25/08/2021

Nordiske virksomheder vil (be)vise vejen i den grønne omstilling via Additive Manufacturing

Med en række partnere vil Dansk AM Hub…

25/05/2021

Sådan skaber vi dansk bæredygtighed gennem Additive Manufacturing

Direktør i Dansk AM Hub, Frank…

19/05/2021

40 millioner skal styrke dansk bæredygtig produktion

Industriens Fond geninvesterer i Dansk…

07/05/2021

Protected: Dansk AM Hub indgår samarbejde med 3D Eksperten

Dansk AM Hub indgår samarbejde med 3D…

18/03/2021

Endnu et vellykket Hybrid-forløb: Virksomheder forbedrer produkter, mens de sparer penge, tid og bliver mere bæredygtige

Læs her om fem virksomheder, som…

17/03/2021

Ny rapport viser global vækst for 3D print trods pandemi

Wohlers report giver en status på AM…

15/03/2021

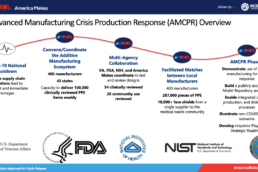

AM udgør et stærkt våben i America Makes’ kamp mod COVID19 – og fremtidige kriser

Læs om hvordan America Makes spillede…

12/03/2021

Webinar-optagelse: AM – Leading the Rebound of American Manufacturing

How do we use Additive Manufacturing…

23/02/2021

Webinar: AM – Leading the Rebound of American Manufacturing

I dette webinar hører vi amerikanske…

11/02/2021

Webinar: Genanvendt plast og 3D print – effektiv grøn omstilling

Genanvendt plast og 3D print er temaet…

10/02/2021

Norden samles for at styrke et fælles fokus på 3D print

Sammen med Alfred Nobel Science Park,…

03/02/2021

Wikifactory is moving its global headquarters from Hong Kong to Denmark

Wikifactory is moving its global…

01/02/2021

Dansk AM Rapport 2021: Potentiale til en bæredygtig fremtid

Dansk AM Rapport 2021 - bliv klogere på…

01/02/2021

Dansk AM Hub søger en udadvendt Chief Technical Officer til nyoprettet stilling i Herning

Vil du være med til at implementere ny…

12/01/2021

Dit juridiske ansvar i markedsføringen af 3D-teknologiens bæredygtige potentiale

Accura advokater har endnu engang…

08/12/2020

Nyt europæisk projekt etablerer produktionsberedskab til fremtidige sundhedskriser

Nyt fælleseuropæisk projekt skal sikre…

24/11/2020

Accuras juridiske anbefalinger til dig, der bruger 3D print

Accura advokater har samlet en række…

22/10/2020

Additive Manufacturer Green Trade Association Announces New Members

Danish AM Hub becomes part of a global…

28/08/2020

Vær bevidst om dit juridske ansvar ved brug af 3D print

Accura advokater har samlet en række…

04/06/2020

The Impact of COVID-19 on the Future of Advanced Manufacturing and Production

Insights from the World Economic…

26/05/2020

Terma reducerer materialeforbrug og produktionstid markant med AM

Hidtil har Terma A/S haft et højt…

15/04/2020

Hybrid: 3D print og sprøjtestøbning skaber adapter til snorkelmaske

I kampen mod Corona har AddiFab med…

07/01/2020

Svenske Prototal AB køber den danske 3D-print virksomhed Damvig A/S

Damvig A/S har indtil salget været ejet…

05/12/2019

Danish AM Hub as winner of German Design Award 2020

In the fall of 2019, Danish AM Hub won…

16/10/2019

3D print vil ændre måden et produkt bliver designet, udviklet og produceret

Under overskriften ’changing paradigms’…

24/09/2019

3D Print kommer til at revolutionere implantat-markedet

Particle3D har med sloganet "We print…

12/06/2019

Dansk AM Hub vil hente udenlandsk kapital til danske start-up virksomheder inden for 3D print

Et nyt initiativ fra Dansk AM Hub skal…

18/01/2019

Innovationskonference: 3D-print og AM-teknologi – en katalysator for stærkere produktion og nye forretningsmuligheder

Dansk AM Hub og MADE inviterer til en…

14/01/2019

40 AM eksperter giver deres bud på udviklingen i 2019

Michael Petch fra medievirksomheden 3D…

08/01/2019

The potential in Additive Manufacturing

07/12/2018

Additive Manufacturing er drivkraften for bilindustriens fremtid

Forbes artikel skrevet af Sarah Goehrke…

27/11/2018

Addifab fordobler omsætningen det første år med 3D print og sprøjtestøbning

Sidste år vandt AddiFab i Jyllinge…

10/09/2018

Dansk AM Hub er dansk anker på nordisk samarbejde om 3D print

Det er første gang der samles et…

07/06/2018

Danske virksomheders konkurrenceevne skal styrkes med 3D print

3D print og Additive Manufacturing er…

06/06/2018

Monoqool var halvvejs i skifteretten – en 3D-printer forhindrede likvidering og grundlagde en millionforretning

Danske virksomheder kan lære meget af…

06/06/2018

Danske virksomheder sakker bagud i milliardstort 3D-kapløb

Med 46 mio. kr. i ryggen skal Dansk AM…

21/03/2018

Siemens investerer stort i 3D print

30/01/2018

Regeringens nye digitale vækstinitiativ vil skabe synergi med AM Hub

I forlængelse af mødet i…

23/01/2018

Huismans 3D printede kran-krog testet til bæreevne på 80.000 kg

Huisman, en verdensomspændende…

22/01/2018

Harvard forskningsprojekt udvikler roterende 3D print metode, der producerer som naturen gør det

Kompositmaterialer, der findes…